Universal Electric Pipe and Bolt Threading Machine

With the due assistance of our deft professionals, we are capable to deliver quality-centralized lot of Universal Electric Pipe and Bolt Threading Machine. We are working in close coordination with the team members and management; they make every endeavor to keep the products piled up safely in our capacious warehouse. By this, we make deliveries in the committed time span.

...more

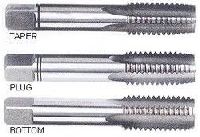

threading tap

Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Size form geometry texture or finish. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

...more

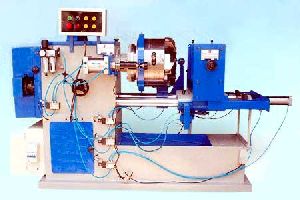

Threading Machine

Functions of this machine: the threading machine is used for cutting external thread on component by chasing method. Hss tangential chasers are used as cutters. Component remains stationery and die head rotates. Matric, bsp, bspt, npt, unf,unc, bsw, acme threads, b.s.f etc. Threads can be cut on this machine depending upon the type of chasers. the machine mainly consists the following:- • base • head stock • saddle • bed type clamping vice • die head

...more

threading dies

Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap. Theoretical knowledge and practical experience are intrinsic in this process. Base material, its heat treatment, and final surface coating are significant factors; but they would be irrelevant without the correct geometry. Tap geometry involves a combination of features tailored to all the above... thread and flute cutting angles, flute pattern, cutting force reduction features. The culmination of these geometrical features is the knowledge we refer to. Our knowledge combined with processes and equipment, allow consideration of all these variables.

...more

Tapered Threading Machine

We are offering Tapered Threading Machine. Used extensively in construction industry, our Tapered Threading Machine is appreciated by the clients for its reliable performance and high efficiency. Features : Improved efficiencyExcellent performanceHighly reliableCost effectiveHigh speedBased on advanced technologyRequires low maintenanceNoiseless operation Used in : Construction industry Components of Tapered Threading Machine : Head stockSaddleJawsPillar Type Clamping ViceBedApron

...more

Taper Threaded Rebar Splicing Systems

The company offers the most applauded taper threaded rebar splicing system for meeting the diverse requirements of numerous industrial segments. Our taper threaded rebar splicing system is designed specifically for ensuring efficient performance. We have pleased the customers by offering taper threaded rebar splicing system at affordable market price. Features : easy installationexcellent performanceoffers full load transferuse if maximum bar section is allowedleast disturbanceno need of lock nutsindependent splice strength benefits : prevents cross threadingtakes several turns for getting back into placeno electricity requiredcost effectiveno need of special tools application areas pilesfoundationscolumnsbeamscore wallsslabsbridgesdamsfuture expansions the mechanical connection shall meet building requirements of developing in tension or compression. The mechanical connection shall be the positive locking, taper threaded type coupler, manufactured from high quality steel. The bar ends must be taper threaded using the manufacturer’s requirements. specifications rebar sizes (mm)external diameter (d)length (mm) (l)thread pitch (mm)16 mm25522.020 mm32742.525 mm36902.528 mm40952.532 mm451052.536 mm501152.540 mm601352.5 click here for more information

...more

steel pipe threading machine

The desire to offer the highest level of satisfaction to our clients induced us to manufacture genuine quality Steel Pipe Threading Machine. Steel Pipe Threading Machine manufactured by us is widely used in pipe, bolt, rod, scaffolding pipe, ERW pipes, steel bars, Rebar, PVC pipes, conduit pipes, GI pipes etc. We are one of the bona fide pipe threading machine manufacturers. These machines are manufactured in such a way that they offer high resistance to heat, wear & tear and abrasion. All these qualitative features have assisted us to stand amid the best thread machine suppliers in India. The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The Steel Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition. Design & Workmanship : The National Cutting Tools Steel Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Steel Pipe Threading Machines and Die Heads. 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/- 4 to 8 do/-

...more

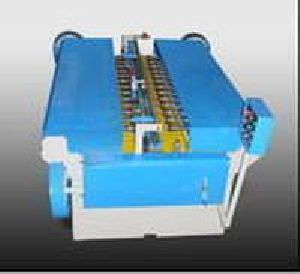

Scaffolding Thread rolling machine

We Stand in the Midst of Specialized Circular Thread Roller Exporters. We Manufacture High Quality Thread Roller from Superlative Quality Raw Materials that Make Them Durable and Highly Resistant to Various Climatic Factors. We are One of the Predominant Flat Die Thread Roller Suppliers from India. These Thread Rollers are Manufactured as per International Standards, Under the Strict Vigil of Our Skilled Staff. as a Result, this Range of Our Unmatched Quality and High Performance Thread Rollers are Widely Demanded in National as Well as International Markets. in Addition to This, We Provide the Facility to Supply Variety of Thread Rolls as per the Client’s Specifications and Requirements. the 3 Rollers Hu-3r Rolling Machine Operates Hydraulically. the Simultaneously and Concentricity of Three Forces At 120º Assure Stability of the Work Piece During the Rolling and as a Consequence the Maximum Geometrical Precision of the Work Piece. the Elimination of the Support Blade Consents a Better Finishing of the Piece and the Execution of Particularly Delicate Profiles. the Machines is Suitable for Rolling Pipes, Lapping Work, Threading with a High Class Precision and for Mass Production of Scaffolding Pipe Jack and Solid Jacks Screws Etc. the Maximum Values Specified Above Can Not Be Achieved Simultaneously. Extra Accessories : All Kinds of Thread Roller, Work Rest Blade (Guide), other special equipments are available on request at extra cost.

...more

Scaffolding Cuplock Welding Machine

We have superior storage facility to keep large product range that we make available. In order to meet elevated quality norms, we keep it updated with modern work methods. Keeping in compliance with the international standards, we ensure that the raw materials used for varied products are 100% certified and quality approved. This helps us in maintaining a set standard of our products. Features : Corrosion resistance Sturdiness Precision-designed Specifications : Item Unit Cuplock / Ring Lock Supply v 220 Phase Nos. SINGLE Frequency Hz. 60 Speed RPM 2 to 10 Motor Drive TYPE AC Inverter Motor TYPE 3-Phase Torch Clamping TYPE PNEUMATIC Length Adjustability mm 150 to 2400 Dimensions LxWxH 11.3 x 2.5 x 5.3 (Foot)

...more

Rod Threading Machine

We are Manufacturer, Exporter and Supplier of genuine quality Rod Threading Machine, which is highly admired by all our clients in the quality cautious market. These machines are highly preferred by the clients as they are easy to use. We are one of the preeminent threading machine manufacturers in India. These machines encompass advanced features that assist us in producing high quality threads at a fast pace. There is a heavy duty geared head box provided for qualitative support to the spindle bearings. Tie rod threading machine manufactured by us offers high resistance to abrasion and heat. The delivery of these threading machines is made well within the stipulated time period. The Rod Threading Machine is used for Cutting External Thread on Rod by Chasing method. HSS Tangential Chasers are used as cutters. Rod remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Type Or Bed Type Clamping Vice Die Head The Rod Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition. Design & Workmanship : The National Cutting Tools Rod threading machines are designed to produce quality threads within the to lerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT Threading machines and Die Heads. 3/8'' to 1.12'' do/- 1/2'' to 2.1/2" do/-

...more

Reinforcing Rebar Coupler

National cutting tools are suppliers of concrete reinforcing materials to the construction industry rebar upsetting technology: cutting: 1) the end of the reinforcement bars is swan square. Cold forging: 2) with the help of patented cold forging, the swan end of the reinforcing bar is then enlarged. With this the core diameter of the bar is increased to predetermined diameter. Threading: 3) an iso standard metric thread is then cut

...more

Rebar Upsetting Machine

We are offering Rebar Upsetting Machine. It is designed and manufactured specifically for setting up a connection of concrete reinforcement bars. The excellent performance and long performing life of our Rebar Upsetting Machine has given a boost to its demand in the global market. Attributes : Specifically designed for the connection of concrete reinforcement barsStronger than otherEnsures bar break under tensile strengthUpsets and thickens the end part of the rebarRaises the rebar areaUnmatched performanceSmooth and trouble free operation

...more

Rebar Threading Machine

Based on advanced technology, Rebar Threading Machine is a revolutionary machine for threading forged ends of reinforcement bars. Rebar Threading Machine is designed for the precise production of Rebar, reinforcing bar, for concrete foundations. With futuristic design, Rebar Threading Machine significantly reduces effort, thus boosts productivity to a great extent. Rebar Threading Machine offers several other benefits such as low operating cost, easy installation & maintenance, non-corrosive housing and fast operation that make it worth buying. We are a Manufacturer, Exporter, and Supplier of Rebar Threading Machine, based in Ludhiana, Punjab. For further technical information, please contact us. Rebar Threading Machine comprises of a Base, Head Shock, Saddle, Bed Type Clamping Vice and Die Head. During the cutting process, Die Head rotates and the bar remains stationary. This machine can be used for cutting a wide range of threads that include Matric, BSP, BSPT, NPT, UNF, BSW, Acme Threads, etc.

...more

Rebar Coupler

PVC Pipe Threading Machine

Our company offers unmatched quality PVC pipe threading machine that is manufactured using superior quality materials. This further ensures high durability and effective performance due to which it is high on demand in the national and international market. We are reckoned as the most outstanding pipe threading machine manufacturers of India. Last but not the least, this PVC threading machine is easily available at the most reasonable prices. The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, MATRIX, BSPT, NPT, UNF,UNC, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:- Base Head Stock Saddle Pillar Or Bed Type Clamping Vice Die Head The PVC Pipe Threading Machines are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with Company Tradition. Design & Workmanship : The National Cutting Tools PVC Pipe Threading Machines are designed to produce quality threads within the to lerance for which they were intended. Head Stock : A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings. The Bed : The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit. The Saddle : The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment. The Apron : The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel. Vice Jaws : The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle. Range of NCT PVC Pipe Threading Machines and Die Heads. 3/8'' to 1.12'' do/- Capacity Pipe & Bolt 1/2'' to 2'' do/- 1/2'' to 2.1/2'' do/- 1'' to 4'' Capacity Pipe 2.1/2'' to 6'' do/- 4 to 8 do/-

...more

Portable Pipe Threading Machine

To pack our products, we have ultramodern machines. The packaging materials are nontoxic, sturdy and reliable. The products remain safe and undamaged in our packaging. We source direct as well as indirect raw materials only from the certified vendors present in the market. Our team of quality experts strictly checks the entire range against varied parameters.

...more

Pipe End Facing Machine

We are a distinguished Manufacturer, Exporter, and Supplier of Pipe End Facing Machine from Punjab (India). Our Pipe End Facing Machine mainly consists of base, head stock, saddle and clamping vice. Before galvanizing and threading, pipes are chamfered from inner, outer and front face, and deburred with the help of Pipe End Facing Machine. Pipe End Facing Machine helps pipes remain stationery while the facing head of the pipe rotates. For manual chamfering, slide of the pipe moves towards facing head.

...more

Pipe Beveling Machine

National Cutting Tools is one of the leading Manufacturers, Exporters and Suppliers of Pipe Beveling Machine. It is used for the purpose of beveling the Pipe End. Pipe is Beveled from the Outer and Front is faced by two different tools. The Pipe remains Stationery and the Beveling Head rotates and comes out of the Head Stock for cutting the Pipe End. It consists of the following:- Bed : The Bed of Pipe Beveling Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as to take maximum Load and absorb maximum vibrations. It is provided with four Nos. Foundation Holes of Dia M20 at four corners of the bed. It is also provided with Four Tapped holes of 5/8 BSW near the Foundation Holes. The Head Stock and Clamping Vice is fitted on the Bed. Head Stock : he Head Stock body of Pipe Beveling Machine is made of Cast Iron. It is Very rigid and sturdy in design. The Head Stock is designed for Four Nos. Spindle speeds. All the Gears are of helical type made out of Axle Forging. The width of gears is 50 mm. The Shifting Gears slide on Splined Shafts. The Shafts are mounted on Heavy Duty Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts. The Main Spindle is mounted on two Taper Roller Bearings mounted in Hard Chrome Plated Ground Sleeve. The Sleeve along with main spindle fitted with Beveling Head is mounted in the Head Stock body and is movable To and Fro along its axis. A Hyd. Cylinder actuated electrically makes the movement of the sleeve in the Head Stock. The Movement of the Sleeve can also be made manually. The Head Stock is Oil Filled. It is provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator. Clamping Vice : The Box Type Clamping Vice is fitted on the Bed. The Vice is provided with Round Clamping Jaws for each size (4, 5, 6, 7, 8,). The Vice will be Self-centering type. The movement of the Clamping Jaws is made by Pneumatic cylinder fitted on the Vice actuated electrically. The Vice will be very rigid and sturdy in design. Machine will be supplied with single clamping vice. Beveling Head : A special Beveling Head will be provided with the machine. Two Tools of HSS will be used, One for Beveling and second for Root Face. The Beveling Tool will be mounted in a special Spring Loaded Tool Holder with a Roller device. It is fitted on the main spindle that is then mounted in the traveling Sleeve.

...more

Parallel Threading Machine

We are offering Parallel Threading Machine manufactured by us is widely appreciated by the clients for its durability, reliability, efficiency and many other noted features. Premium quality material is used for manufacturing unmatched performance yielding Parallel Threading Machine for complete customer satisfaction. Attributes : Noiseless operationHigh efficiencyExcellent speedUnmatched performanceLow maintenanceAbility to work under severe conditionsCost effectiveEnsures accurate threading Demanded by : BuildersCivil contractors

...more

Parallel Threaded Coupler

We are offering parallel threaded coupler. the company has designed parallel threaded couplers for reinforcing bars; as they produce full strength to the joint rebar connection. Jointed reinforcing bars are cut square and enlarged using cold forging process so that their diameter can be increased and make the joint stronger. We make available parallel threaded couplers attached with reinforcing bars for efficient performance. types rotatable rebar splicenon-rotatable rebar splicenon-rotatable rebar splice with lock-nutdifferent diameter splice features 100% load transmission can be availed through full tension splicesolves bar congestionoffers better flow of concretecontinuity of reinforcing bars in ensuredsteel wastage is reduced with no overlappingreduced reduction of bar cross section areaensures full traceability of materialeasy installationshortens construction cycle time application areas pilesfoundationscolumnsbeamscore wallsslabsbridgesdamsfuture expansions reinforcement bar coupling parallel system cutting : the end of the reinforcement bars is sawn square.cold forging : with the help of cold forging, the sawn end of the reinforcing bar is then enlarged. With this the core diameter of the bar is increased to pre determined diameter. Threading : an iso standard metric thread is then cut. sizethreadouter diameter (mm)length (mm)mm pitchweight(kg)12m16203020.06216m20264220.08218m2229452.50.11420m2432482.50.15322m27365430.20725m30406530.30328m33447030.39832m36507830.60836m3956883.50.60840m4562954.01.138 installation of nct re- bar couplers good quality shear cut bars with sharp perpendicular cutting or saw cutting may be used. The threading is provided on bar ends with proprietary branded threading equipment and thread cutting toolsthreading of reinforcement bars must be carried out as per nct re-bar couplers by trained operator. The thread checking gauge is used for checking the threads. The threads shall be covered by thread protection plastic cap while storingthe bent bars may be threaded on threading machine provided straight length of the bent bar-end to be threaded is more than 0.5 m. If not so, the bars may be threaded in straight lengths, connected thoroughly and bar bending is carried out subsequently. The bent must be minimum 100mm apart from thread bar endthe bar is connected to coupler sleeve initially by hand tightening and then with pipe wrenchthe nct re- bar couplers full strength threaded butt joining that achieves strength with fully engaged threading of coupler and reinforcement bars. Therefore, it is essential to ensure adequate tightening of joining connection for effective load transfer capacitymodel nct-1.1/2"model nct-2.1/2"saddle movement12"-14"14"-16"spindle speed range 60-9060-90number of spindle speed 22threading capacity3/8" to 1.1/2"1/2" to 2.1/2"production per hour 60-8060-80h.p. Required3 h.p. 960 rpm7.5 h.p. 960 rpmlead screwn.an.aweight (kg)550990 the bar or re-bar threading machine is used for cutting external thread on bars by chasing method. Hss tangential chasers are used as cutters. Bar remains stationery and die head rotates. Matric, bsp, bspt, npt, unf,unc, bsw, acme threads b.s.f etc. Threads can be cut on this machine depending upon the type of chasers. The machine mainly consists the following: basehead stocksaddlebed type clamping vicedie head

...more

Manual Multi Spindle Drilling Machine

Our investment in the well-structured warehouse has paid off well. We have successfully installed up-to-the-minute warehouse management software to keep the entire lot in a safe and organized manner. With the due assistance of our deft professionals, we are capable to deliver quality-centralized lot of Manual Multi Spindle Drilling Machine.

...more

machine tap

Your tapping requirement may be unique for various reasons, but one common requirement in all applications is successful tapping. Some examples of why your application may be special. Material characteristic such as swarf type, elasticity, strength and hardness. depth of hole thread size pitch thread form reach holding There are essentially four qualities in successfully designing and manufacturing a tap.

...more

liquid painting plant

By making use of quality packaging material, we pack the entire lot in a safe manner ensuring zero damage at buyer's end. The packing procedure is conducted under the guidance of experts. We are comfortable with traditional payment options as well as the modern ones. Our payment related policies are client friendly. Our payment procedures are transparent, safe, and secure. Liquid Painting Plant having following items : Liquid Paint Tanks – 1 Nos. Dripping Tray - 1 no Oil Fired Curing oven (Straight Type) – 1 Nos. Overhead Motorized Conveyor, with support Structure – 1 Set. Electrical Control Panel – 1 Set. Painting, and Finishing etc. – 1 Lot.

...more

Ledger Welding Machine

We are associated with a team of deft professionals who make sure that the offered lot is prepared using the finest grade material only. For this, we have tied-up with the prominent vendors in the market. With exceptional transportation facilities, our diligent team delivers the product basket in the committed time span. Technical Specifications : I Ledger welding Double Side Electric Supply - Single Phase 220 Volt HZ 50/60 Speed - 2 to 10 RPM Motor Drive - AC Inverter Type Motor - Type AC 220-Volts-3-Phase Torch Clamping - PNEUMATIC Length Adjustment - 150 to 2400 mm Dimension - L x W x H 11.3x2.5x5.3 (Foot) Key Features - High production , Easy to operate, Easy to maintain, Uniform welding results

...moreBe first to Rate

Rate ThisOpening Hours