Wire Drawing Lubricants

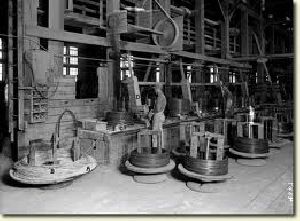

Wire drawing is a manufacturing process used to reduce or change the diameter of a wire or rod by pulling the wire or rod through a single or series of drawing die(s). Wire drawing is the process used to manufacture the wire for all types of applications. There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels, and stringed musical instruments. There are a variety of metals that are made into wire, the most common being steel, copper, brass, aluminum, stainless steel, and tungsten. Wire Drawing Process During the wire drawing process, no material is shaved off, the wire simply gets longer. The material is cold-worked and hardens (and also increases in tensile strength) through each step. Processes used in wire drawing include wet and dry drawing. Methods used are single draft drawing and continuous drawing. Both process and method used depend on requirements of the finished product. The main process steps are: Wire head is pointed by wire pointing machine, Wire coils are placed on a ring, The pointed end is passed through a die to the drawing machine, Reduction is achieved in four stages, Drawn wire is coiled on bull block There are several types of drawing machines. These have been grouped as follows :- Drawing frames , Bull blocks, & motor block, Multiple-drawing machines, Fine-wire machines, Turk's - head shaped - wire drawing machines, Drawbenches. The following lubricants are recommended for Wire Drawing applications.

...more

Welding Electrodes

Graphite Powder is used in Arc Welding Electrode manufacture as a component in the Flux. Graphite’s high oxidation resistance enables it to combine with the molten weld metal material. Precise Graphite particle size distribution ensures easy extrusion and elimination of cracks in the flux coating. Graphite addition to the flux is primarily in hard facing electrodes and also in nickel and ferro-nickel core wire electrodes used for welding of cast iron requiring machining capability.

...more

WARM FORGING LUBRICANTS

Warm forging has a number of cost-saving advantages which underscore its increasing use as a manufacturing method. The temperature range for the warm forging of steel runs from above room temperature to below the recrystallization temperature, or from about 800 to18000F. However, the narrower range of from 1000 to 13300F is emerging as the range of perhaps the greatest commercial potential for warm forging. Compared with cold forging, warm forging has the potential advantages of: Reduced tooling loads, reduced press loads, increased steel ductility, elimination of need to anneal prior to forging, and favorable as forged properties that can eliminate heat treatment. The following lubricants are recommended for warm forging applications.

...more

UPSET FORGING LUBRICANTS

Upset forging, also called hot heading, is a process by which the cross-sectional size of a bar is increased, either at an end or at some point along its length. It is done on specially designed upsetting machines, using closed dies to control size and shape. Typically, dies have several stations, and the parts are formed progressively by moving the parts from one die station or cavity to another until the forging is complete. Heads of bolts, valves, single and cluster gear blanks, artillery shells, and cylinders for radial engines are examples of parts made by upset forging. This same process, when performed cold, is called cold heading. Cold heading makes possible the economical mass production of fasteners; such as nails, screws, bolts, hinge pins, and rivets. The following lubricants are recommended for Upsetting applications.

...more

Specialty Lubricants

REFRACTORIES CERAMICS

Refractory materials must be chemically and physically stable at high temperatures. Depending on the operating environment, they need to be resistant to thermal shock, be chemically inert, and/or have specific ranges of thermal conductivity and of the coefficient of thermal expansion. Natural Graphite is the key additive in many specialized refractories like magnesia-carbon bricks

...more

process lubricants

Oxeeco produces several lubricants for meeting the challenges in process industry such as Metal Forming operations in Forging, Upsetting, Extrusion, Deep Drawing, Casting, Wire Drawing and Glass bottle manufacturing etc Our products are especially designed to suit various temperatures, pressures and other environmental conditions using high purity solid lubricants, special additives, binders and other chemicals. Our mission during last 3 decades has been to develop products for a diverse range of applications. Many of these products have been well demonstrated to a large segment of customers and have been upgraded continuously by our R&D expertise in close interaction with end users. We are also in a position to meet the challenges of customers by designing products to meet individual requirements and provide solution.

...more

PRECISION FORGING LUBRICANTS

Precision forging normally means close-to-final form or close-tolerance forging. It is not a special technology, but a refinement of existing techniques to a point where the forged part can be used with little or no subsequent machining. Improvements cover not only the forging method itself but also preheating, descaling, lubrication and temperature control practices. The decision to apply precision forging techniques depends on the relative economies of additional operations and tooling vs. elimination of machining. Because of higher tooling and development costs, precision forging is usually limited to extremely high quality applications. The following lubricants are recommended for precision forging applications.

...more

powder metallurgy

Powder metallurgy is an increasingly important manufacturing process for metal components primarily in automotive industry. Graphite because of its unique physical and chemical characteristics forms an important component of the powder metallurgy mix. Oxeeco’s knowledge derived from over 40 years of working closely with powder metallurgists enables it to manufacture many grades to meet the complex requirements of the powder metallurgy industry. Consistent quality enables the customer to produce high quality components with negligible defective components.

...more

metal forming lubricants

In Metal forming operations, desired dimensions of the component are achieved by imparting plastic deformation to the work piece in the solid state. Any specific component can be made using a number of materials by variety of processes at various temperatures. Metal deformations are introduced through the application of external forces to the work piece, these forces being in equilibrium. With the application of load to the work piece, internal stress and displacements are generated causing shape distortions. If the loads are low, then with the release of the loads, the internal stresses will disappear and the work piece will be restored to its original shape. Oxeeco lubricants help in achieving metal formation/deformation by controlling friction and wear at the interface surfaces. Our lubricants are specially designed not only to minimize friction and wear but also protect the surfaces by forming a film providing hydro-static or hydro-dynamic lubrication. Our lubricants are prepared using high purity Graphite with fine particle size 3-5 microns average which can easily fill-up the asperities of sub-micron level and provide uniform thin film on the surfaces of interfaces. Therefore our lubricants provide excellent lubrication and good metal flow properties during the metal deformation process and result in superior surface finish. Our lubricants are formulated to provide extended die life during the metal forming process. Our lubricants cater to following processes – Forging Upsetting Extrusion Deep Drawing Casting Wire Drawing

...more

maintenance lubricants

Oxeeco’s Specialty maintenance products are born out of a need to overcome special problems being focused in the field. Constant interaction between maintenance personnel in industry and Oxeeco’s R&D teams has resulted in an extensive range of products designed to meet the most exacting working conditions. The company was established in 1970 to manufacture high purity graphite, an activity in which it has maintained continuous leadership. The company soon diversified into manufacturing process and maintenance lubricants, specialty coatings and industrial cleaners. Oxeeco has one of the best equipped laboratories enabling most tests to be done in-house. Products undergo rigorous testing under stimulated conditions prior to extensive field trials. Constant improvement has enabled most products to be the market leaders in their category. Our high quality products and dedicated services have helped build relationships of mutual trust and confidence with a host of world class organizations, which have lasted over three decades. Our speciality maintenance products consist of a vast number of specially formulated lubricants, coatings and cleaners. Reducing maintenance by increasing component life cycles and eliminating breakdowns is a major contributor to productivity and profitability in industry today. Operating conditions combining high temperatures, harsh environmental conditions, corrosive atmospheres, extreme pressures and high speeds pose over greater challenges for the development of lubricants and coatings. Using advanced techniques and materials Oxeeco has developed a range of products, which will meet the requirements of even the most severe operating conditions. Oxeeco maintains the highest standards of manufacturing to protest the environment and is constantly working towards ensuring that its products are environmentally friendly and do not pose any health hazards to the users. Oxeeco’s products find use in all segments of industry, the transport sector, consisting of railway, shipping, aerospace and automotive applications, the energy sector, mining and metallurgical industries; food processing and pharmaceutical mfrs, agriculture, textiles, chemical industry, electrical and electronic industry.

...more

Lubricants

Graphite is widely used as a solid lubricant additive in the manufacture of a wide range of colloidal suspensions, greases and solid film lubricants. Graphite’s lamellar structure provides low shear in the direction of the motion, at the same time provides resistance to high lateral loads. Solid Graphite powder is dispersed in Oil, Water and Solvents to provide an effective barrier in metal to metal contact. It is widely used as an additive in lubricants used in metal working processes such as Forging, Extrusion, Molding, Die Casting, Stamping etc.

...more

Glass Mould Lubricants

There are, currently, two primary methods of making a glass container — the blow and blow method and the press and blow method. In both cases a stream of molten glass, at its plastic temperature (1050°C-1200°C), is cut with a shearing blade to form a cylinder of glass, called a gob. Both processes start with the gob falling, by gravity, and guided, through troughs and chutes, into the blank moulds. In the blow and blow process, the glass is first blown from below, into the blank moulds, to create a parison, or pre-container. Theparison is then flipped over into a final mould, where a final blow blows the glass out, in to the mould, to make the final container shape. In the case of press and blow process, theparison is formed with a metal plunger, which pushes the glass out, into the blank mould. The process then continues as before, with the parison being transferred to the mould, and the glass being blown out into the mould. Oxeeco's grade "Lubricote-X 9" gives better mould lubrication of glass bottle moulds

...more

glass bottle mould

There are, currently, two primary methods of making a glass container — the blow and blow method and the press and blow method. In both cases a stream of molten glass, at its plastic temperature (1050°C-1200°C), is cut with a shearing blade to form a cylinder of glass, called a gob. Both processes start with the gob falling, by gravity, and guided, through troughs and chutes, into the blank moulds. In the blow and blow process, the glass is first blown from below, into the blank moulds, to create a parison, or pre-container. Theparison is then flipped over into a final mould, where a final blow blows the glass out, in to the mould, to make the final container shape. In the case of press and blow process, theparison is formed with a metal plunger, which pushes the glass out, into the blank mould. The process then continues as before, with the parison being transferred to the mould, and the glass being blown out into the mould.

...more

Gaskets

A gasket is a mechanical seal that fills the space between two mating surfaces, generally to prevent leakage from or into the joined objects while under compression.

...more

Friction Materials

Graphite in view of its lamellar structure is widely used in the production of friction materials. In the direction of motion the lamellar structure provides easy shear resulting in low friction. In highly loaded stationary surfaces, the lamellar structure has sufficient strength to prevent contact between the surfaces under pressures.

...more

forging lubricants

The most versatile technique of metal forming. The advancement in the metal forming technology, wherein plastic deformation of metals take place at elevated temperatures into required size, shapes using compressive forces by a hammer, press or upsetting machines etc. The process parameters such as temperature, pressure & different kind of materials classify the processes into Hot Forging, Cold Forging, Warm Forging & Precision Forging. The recent advancement in the forging industry is poising every day new challenges to lubricant manufacturers. OXEECO with its continuous R&D effort and close inter-action with end users has developed several lubricants to meet most of the challenges from time to time.

...more

dry film lubricants

die casting lubricants

Die castings the process of forcing molten metal under high pressure into mold cavities (which are machined into dies). Most die castings are made from non-ferrous metals, specificlly Zinc, Copper, Aluminium, Magnesium, Lead and Tin based alloys, although ferrous metal die castings are possible. The die casting method is especially suited for applications where a large quantity of small to medium sized parts are needed, ensuring precise surface quality and dimensional consistency. This level of versatility has placed die castings among the highest volume products made in the metal working industry. The following oil base lubricants are recommended for die-casting applications.

...more

colloidal graphite

COLD FORGING LUBRICANTS

Most forging is done as hot work, at temperatures up to 23000 F, however, a variation of impression die forging is cold forging. Cold forging encompasses many processes – bending, cold drawing, cold heading, coining, extrusions and more, to yield a diverse range of part shapes. The temperature of metals being cold forged may range from room temperature to several hundred degrees. The following WATER BASE lubricants are recommended for cold forging applications.

...more

BATTERIES FUEL CELLS

Graphite is an excellent conductor of electricity. This property combined with its chemical inertness makes it an ideal component in various electro chemical applications such as all type of batteries, dry cells, fuel cells etc. Carefully prepared particle size distribution ensures optimum use of the graphite powder for enhanced electrical conductivity and electrical charge storage.

...more

extrusion lubricants

Graphite Powder

Be first to Rate

Rate ThisOpening Hours