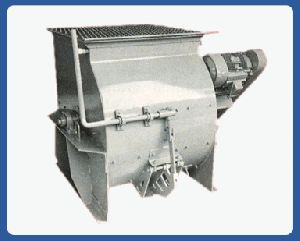

Single Shaft peddle Mixer

Hydrill Equipments Hydrill Equipments offer Single Shaft Peddel Mixer - Unitised steel frame construction minimize vibration and wear on the machine and support structure mixer. Tub wall are cylindrical for easy, energy saving and tumbling action to give the batch uniformity and need for top equality mix.

...more

Reverse Discharge Mixer Machine

Reverse Discharge Mixer Machine Concrete is most commonly used construction material known for its proven strength & durability. It is made from naturally available materials like stone aggregates & sand mixed with cement and water. Present day RCC structural designs need high quality concrete mix, consistent in strength & workability, as concrete is a prime ingredient next only to steel. Standard Features Reversible Drum thru push button. Skip Bucket lifted / lowered hydraulically with a simple lever. Life lubricated sealed bearings for rollers. Grease cups / nipples for rotating parts. Power transmission thru ‘V’ belts for smooth operation. Analog gauge to read loads in bucket. Level indicators on water & oil tanks. Dis-assemblable axle for transportation on vehicles. Hand lever for cranking in case of power failures. Auto water flow controller (only on electronic machine) Construction Special Features Load cell based digital weighing system. Liquid admixture dosing system Multi bucket configurations for individual aggregates loading separately Four wheel chassis External weigh batching (to improve productivity) Legs with screw jacks for easy levelling

...more

Paver Block Making Machine

Paver Block Making Machine - HYDRILL 800-HP is a stationery type concrete pavement block making machine specifically designed for super fine blocks. Two operators can work simultaneously on this machine, from both sides. Mould is filled manually. A hydraulically operated mould opener is incorporated on either sides of the machine for easy opening of the mould. HYDRAULIC PRESS Specifications : Hydraulic Press(Upward): 60 ton Power : 5 HP Oil Tank Capacity: 40 litres Production: 900 to 1200 blocks / shift DRUM MIXER Specifications : For Colour Mxer Motor : 2 HP Loading Capacity : 150 to 250 Kg / batch

...more

Pan Mixer / Mobile Batching Plant

Pan Mixer : The Pan type mixer is designed to allow to operate on a wide range of application including Dry, semi dry or zero slump mixing for concrete and other mixtures. The mixing pan is made of steel plate of substantial thickness. The bottom and wall are mounted anti wear alloy steel liner. Spring loaded mix arms are fitted in the rotary head and can be adjusted to compensate wearing. The gear reducer is directly connected to electrical motor. Mobile Concrete Batching Plant Specification: Load Capacity : 0.5 cu.m3 / (400 kg Aggregate). Output : 6 cu.mt / hr Power : 15 HP Discharge : Door opened by hydraulic. Input : Hopper lifted by hydraulic cylinder. Load cell : Attached to hopper base Mobile Concrete Batching / Mixing Plant : Salient Features : Very slim and compact design. Plant can be erected and commissions within two days. Remarkably cost efficient. Plant operations is very salient, in & clean surrounding. Least maintenance of plant, due to less wear & tear of parts. Complete plant can be transported in the 40ft, trailer. Water tank, pump addition burner and addition pump inbuilt. Optionals : Online printing system Discharge belt conveyor Fly ash feeding system Cement storage silo

...more

Interlock / Stabilized Soil Block Machine

Interlock Block / Stabilised Soil Block Machine provides an opportunity to use locally available or waste near construction site like excavated soil at site or Fly ash as main raw material to get alternative to burnt bricks. Interlock Block / Stabilised Soil Block Machines are mobile / static and can be easily moved from site to site. Hydrill -1000-HSB blocks having tounge and goove interlocking making a mechanical bond requiring no or minimal mortar. Blocks are smooth in finish and the walls may be left exposed, plastered or coloured with cement paint. Specifications: Hydrill -1000 HSB is a Stationary Type Interlock Soil Block Making Machine with pressing Capacity 20 to 50 tons This machine is available in two models Manual & Automatic Number of blocks per hour : 120 / 250.

...more

Hydraulic Block Splitter

Hydril Equipments - This Machine is a hydraulically operated shearing machine used to shear concrete blocks, which gives the sheared face a granite like surface. Hydraulic Block Splitter Specification: Semi Automatic Operation. Blade : 600 mm long. Power : 7.5 HP. Shearing Height : 40 to 230 mm. Cutout force : 20,000 kg Hydraulic pressure : 115 kg / cm2 Fully Automatic Operation. Blade : 600 mm long. Power : 20 HP. Shearing Height : 60 to 230 mm. Cutout force : 20,000 kg Hydraulic pressure : 115 kg / cm2

...more

Fly Ash Brick Making Machine

We manufacture Fly ash Brick Making Machine which are capable of making bricks from fly ash. This brick making machine sturdily designed has excellent capacity and speed to handle big output demands. Raw materials: Fly Ash, Lime, Zibsem, Quarry dust, Iron Oxide, etc. The specifications of Rotary Hydraulic Press: CapacityPowerPressing CapacitySize of BlockHydraulic SystemHydraulic cylinderElectrical SystemFeedWeight : 1500-2000 bricks per hour: 15 HP: 30 Tons: 230 X 110 X 75(standard) & 230 X 200 X 100: Proven hydraulic system with solenoid valves, to operate: Used for pressing & rotation of table by low speed high torque motor: PLC is incorporated to operate hydraulic system automatically: Conveyor or manual: 2000 kg approximately (Rotary Hydraulic Press ) The specifications of Pan Mixer : CapacityPowerMaterial Charge Material DischargeMixing : 500 kg / batch: 20 HP: Manual: Manual: Two heavy cast rollers and hard faced scrappers. (Pan Mixer)

...more

Designer tile making machine

Designer Tile Making Machine : Vibrator table has been specifically designed for high production wet cast concrete products using wooden carrier frames supporting plastic mould. The moulds with green concrete are kept for initial strength achieving over 24 hours. Then tiles are demoulded from the plastic mould and kept in controled atmosphere for three days. Then laquer coating can be applied for added attractiveness and wear resistance. Longlasting colour faces can be done by adding white cement with colour pigments. Colour pigments with white cement and sand can be mixed in tile mixer and aggregate with grey cement will be mixed in conventional concrete mixer. Vibrator table Specifications : Production Capacity: 4000 sqft / shift Power: 1.5 HP Per Table X 2 = 3 HP Vibrating Table Size: 3000 x 830 Overall Dimensions: 7900 x 900 x 1000 mm (L X B X H)(Approximately) Weight: 500 Kg (Approximately) Maximum Height of Tile : 100 mm Maximum size of Tile : 600 X 600

...more

concrete block machine

Concrete Block Making Machine The frame consists of stable, compact welded box construction made out of steel channel or square pipe with sufficient wall thickness. The guide pillar for mould and compactors head are solid steel shaft made out of alloy steel material. The guide bearing for mould and ram are of phosphor brose material and extra long in order to ensure perfect guiding. The filling box is freely suspended in a special guiding device. Due to this fact, wear on mould and filling device is reduced. The filling box is moved by double acting hydraulic cylinder. Above the filling box big storage hopper is attached. The filling box table, filling box systems and storage hopper are connected to gather so that changing of another mould corresponding height is balanced quickly with less effort. Machine equipped with hydraulic actuated pallet feed with collapsible catch to push forward the pallet on the vibrate table. The seat of mould head is equipped with synchronized connecting rod so that both sides of two end of mould is up and down synchronously and reduce the ware between sleeves and columns. VIBRATION: A piece all steel table is carried on rubber – metal buffers with two special vibrators which are mounted at the bottom of table. Vibrator is run by two motor of reputed make. HYDRAULIC SYSTEM: Pumps, cylinder, solenoid valves, pressure control valves as well as other hydraulic parts are well tried trade marked components. Hydraulic pumps are gear type from DYNAMIC HYDRAULICS or BOSH, solenoid valves are ATOS or REXROTH. Electrical motor will be of reputed make. Hydraulic capacity will be 150 to 400 liters shell and tube cooler will be mounted on the tank.The hydraulic power pack is provided with necessary solenoid operated valves, flow and pressure control valves, which can be set to the desired options depending upon the product to be manufactured.PALLET FEEDING: Pallets are stored in a pallet magazine and fed in to the machine one by one through hydraulically operated positioning mechanism. The same mechanisms shift the pallet with a green block into the block receiving conveyors.FACE MIXING UNIT: The face mix unit is an option part of the basic machine. The unit comprises of manually/auto operated feeding car, its support table and rail. Feeding car is provided with wheels to freely move on the rails. Material in the car is filled manually.ELECTRICAL SYSTEM: 440 Volts electrical control panel to control entire operation by push button switches. All relays and contactors are reputed make like SEIMENS etc. PLC is used to run in automatic, limiting and positioning movement of the various motion is achieved through the proximity switches. BLOCK RECEIVING CONVEYOUR: Lengths approximately 5 meter. Designed as belt convey our, frequently controlled for the transport of green block from block machine to the pallet stacker.CLEANING BRUSH: Provided with rotating brush with pp material. Drive via 0.5 HP motor to sweep off the brushes on the green block. Brush body is in total exchangeable.

...more

Block Cutting Machine

concrete hollow

concrete pavement

Construction Equipment

Brick Making Machines

paver block making machines

Concrete Mixer

Cold Forging

Be first to Rate

Rate ThisOpening Hours