Wire Mesh Conveyor

Being the key suppliers for Belt conveyors to our esteemed clients, we are also engaged in manufacturing, supplying and exporting a wide range of Wire Mesh Conveyor Belts. Our products are developed using premium quality raw material and latest technology to ensure that finished products are met with international quality standards & norms.

...more

wire mesh belt conveyors

Wire Mesh Belt Conveyors are developed using premium quality raw material and latest technology to ensure that finished products are met with international quality standards & norms. The key features of wire mesh belt conveyors are Corrosion Resistance, Sturdy construction and Low maintenance. They also can be used in a variety of conditions to conveyor hot, cold, or oily products in oven, cooling, carrying cold items from a freezer, hot food items or other special conditions.

...more

Wire Belt

The key features of wire mesh belt conveyors are Corrosion Resistance, Sturdy construction and Low maintenance.They are suitable for any application, like including closed wire mesh belts for flexibility and conveying small parts, belts which having large opening or for easy flow of water or air and for cleaning of products and smooth surface belts for easy and accurate transfer.

...more

Troughed Belt Conveyors

Troughed Belt Conveyors The belt is supported on slider deck or rollers mounted at 20°, 30° or 45°, two, three of five roller Troughed form. They offer an efficient and excellent means of transporting materials that are meant for transportation in bulk, over small or large distances continuously. Troughed belt conveyors can take numerous forms and are being used in many different applications with tremendous success.

...more

Telescopic Conveyors

Telescopic systems, also known as Booms or extendable conveyors, will loadunload virtually any loose item quickly, safely and efficiently. By extending directly into the Truck Trailor without the need of support we will significantly reduce loadunload times. Our systems are modern and robust in design to provide our users superior service and reliability. Telescopic Roller Type Boom Belt Type

...more

Screw Conveyors

Screw Conveyors in design and maintenance friendly, they provide a low cost,They are available in wide range of options to suit various requirements. Screw conveyor system is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials.

...more

Roller Conveyors

Roller Conveyors are the most proper choice when you need to side load, push off, accumulate a product or adjust pressure on carrying rollers.A belt over roller conveyor is a multi-type conveyor utilizing both rollers and a belt. They are mostly used in industries which are in need of transporting light to medium weight loads and in either inclines or declines.

...more

Multidischarge Conveyors

Multidischarge Conveyors in a single direction, up or down with multiple discharge chutes and entry locations for high system flexibility. Compact designs, efficient timing belt technology and optimized cycle times enable maximum throughput.

...more

Modular Flex Conveyors

Modular Flex Conveyors in many applications possibilities Straight and curved sections can be combined into a single system and increase production efficiency. Elevate, accumulate, distribute, divert, flip, turn or push the products, we can easily do it by using our flex conveyors. These types of conveyors are highly suitable when the production requires horizontal transport between case packers, cartoners, in-case fillers, shrinkstretch wrappers or bulk. packers.

...more

Mesh Belt

Wire Mesh Belts come in wide range of types, from wide-gap honeycomb belts to tightly-knit chain belts. Both allow air (or liquids) to circulate around the products being conveyed, and hence can be used to 'drain products, or to warmcool them in transit. Wire Mesh conveyors are lighter-duty than their chain-mesh counterparts, and make a very cost-effective solution where the products being conveyed are relatively light. They are suitable for any application, like including closed wire mesh belts for flexibility and conveying small parts, belts which having large opening or for easy flow of water or air and for cleaning of products and smooth surface belts for easy and accurate transfer.

...more

Gravity Roller Conveyor

Roller conveyors are the proper choice when you need to side load, push off accumulate a product or adjust pressure on carrying rollers Roller conveyor types are chain off, rollers, belt driven, line shaft driven, accumulation, or non‐powered (gravity). Using roller conveyors instead of slider bed conveyors adds versatility to the type of transfers, diverters and stops that can be used in a system. Rollers are available in mild steel, galvanized, plastic or stainless steel. A gravity conveyor having a track of parallel tubular rollers set at a definite grade, usually on antifriction bearings, at fixed locations, over which package goods which are sufficiently rigid to prevent sagging between rollers are moved by gravity or propulsion. A belt over roller conveyor is a multi-type conveyor utilizing both rollers and a belt. They are mostly used in industries which are in need of transporting light to medium weight loads and in either inclines or declines.

...more

grain elevator

grain elevator can be also triangular in cross section and set close to on the belt with little or no clearance between them. This is a continuous bucket elevator. Its main use is to carry difficult materials at slow speed.

...more

Flexible Conveyor

This type of belt conveyor system has many of the benefits of the original conveyor system. Due to its modular design, the conveyors are easy to design and assemble to match your specific needs. The added advantage of a side-flexing wide belt permits effective transport and accumulation in several different configurations.

...more

Flat Belt Conveyors

Flat Belt Conveyors It is mostly used for transporting light and medium-weight loads between different units of a company like operations, departments, levels, and buildings. The system provides considerable control over the orientation and placement of the load. The belt is roller or slider bed supported; the slider bed is used for small and irregularly shaped items.

...more

Excavayors

Excavayors the speed can be varied depending upon the capacity need. Positioning and over-travel limit switches assure proper conveyor positioning all the time. We can design product movement configurations in Z Flow, C Flow, and Right Angle Flow -- combination and can be reversible.

...more

elevator accessories

Elevators: Such styles of elevators are used in grain handling facilities we are all familiar with along rivers, ports or on the farm. The elevator buckets discharge product freely by the use of centrifugal force.

...more

Drag Conveyors

Drag Conveyors are very similar to scraper conveyors both in function and the types of materials handled. Drag chains normally run in the material on the bottom of the conveyor trough. Several drag chain strands, operating side by side in a trough are very common in this type of conveyors and are used for heavy loading and unloading.

...more

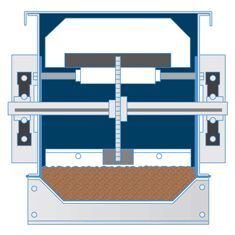

DRAG CONVEYOR

Drag Conveyors are designed and engineered to provide long life and durability with minimum maintenance. Fully enclosed, dust‐tight, and quiet operations assures fast, gentle movement of bulk materials. Extra heavy chain features UHMW polyethylene faced flights for positive flow and reduced friction.

...more

Drag Chain Conveyor

Drag Conveyors are designed and engineered to provide long life and durability with minimum maintenance. Fully enclosed, dust‐tight, and quiet operations assures fast, gentle movement of bulk materials. Extra heavy chain features UHMW polyethylene faced flights for positive flow and reduced friction. Drag conveyors are used to handle bulk materials in many industries. They are very similar to scraper conveyors both in function and the types of materials handled. Drag chains normally run in the material on the bottom of the conveyor trough. Several drag chain strands, operating side by side in a trough are very common in this type of conveyors and are used for heavy loading and unloading. These types of conveyors are used to handle abrasive bulk material such as sand, coal, ashes, coke and cement. They are also used to handle other materials such as sawdust and wood chips. In fact they can be used to convey just about any bulk material that can be discharged by gravity. Such conveyors mostly find use in Construction, Mining and Sand Industries.

...more

Side walled Conveyors

Cleated and Side walled Conveyors are the accuracy of the cleat spacing and durability of the cleat in the application. We have the largest selection of cleats for cleated belt systems, including different heights and cleat angles.Cleated belt conveyor serves many purposes. They help move product up inclines, as well as stage product to operators or to provide predictable spacing on a line.

...more

Chain Conveyors

Chain Conveyors is well qualified to make reliable recommendations on chain conveyor. A chain conveyor consists of one or more endless chains that travel the entire conveyor path. Loads are carried directly on the chain links or on specially designed elements attached to the chain. We manufacture following types of Chain Conveyors.

...more

Bucket Elevators

Bucket Elevators are designed to cover practically every need in elevating loose bulk material. For every material there is a choice of one or more types and sizes which will serve your needs.A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials (most often grain or fertilizer) vertically.

...more

Bucket Conveyors

Bucket Conveyors are designed to gently transport a variety of free flow Bulk materials in Dry, Semi-Dry Moist conditions. These units are extremely adaptable to deliver products to Multi Locations from Single or Multi Source of Supply through its variety of Discharge locations stations. The conveyors allow vertical transportation. The material transport is without spillage and contamination, the closed conveyor design prevents dusting. Variety of configuration allows installation of the bucket conveyors on sites with very limited space. The buckets are bins fixed to the conveyor belt or guide chain, they load the material, transport it to the conveyor top and at the highest point unload the conveyed material.

...more

Belt Conveyor System

Belt Conveyor System are most economical solution of transporting bulk materials at high rates over great distances. They are used for horizontal inclined and declined movement of loads. In Belt conveyor systems, the belt is supported on rollers or on slider bedplate depending upon the need and applications. Not only it acts as a lifeline to a company’s ability but also helps in effective movement of its product in a timely fashion.

...moreBe first to Rate

Rate ThisOpening Hours