Tefc Foot Mounted Motor

Salient Features Simple Construction & Installation Simple Wear Adjustment of Brake Brake with Dust Protection Ring & Manual Release Provision Adjustable Brake Torque High Operating Frequency & Reliability Coil with Class 'F' Insulation All Metal Parts are Rust Protected. Working In absence of power the braking torque is generated by several compression springs whose axial spring force presses the armature plate against the rotor which in turn is pushed against the mounting flange. When power to the brake and motor is supplied at the same time brake coil produces strong magnetic field and pulls the A.P. against the compression springs force towards the stator (Brake Coil) over the air gap and rotor becomes free to rotate. The attraction of the A.P. and returning to its original position takes place instantaneously and thus fail safe nature is ensured in case of power failure. Motor can also be supplied with brake Type EFMB and combination Type ECBC Ordering Information Make of Motor Type of Motor Frame Size Brake Type Brake Size Note: 1 Nm = 0.012 Kgm = 0.737 Ib-ft = 10.2 kgcm Keyways to Indian standard / Din Standard. Standard Voltages 24 VDC ; 96 VDC ; 190 VDC ; other voltages on request.

...more

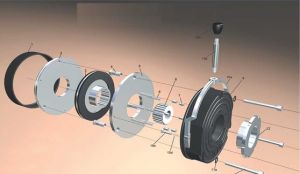

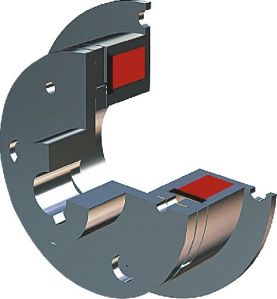

spring loaded fail safe brake

salient features compact robust unit simple wear adjustment high operating frequency with manual release provision. coil with class 'f' insulation all metal parts are rust protected. two friction surfaces low power requirement working of efsb the braking torque in excel spring loaded fail safe brake is generated by several compression springs (6) whose axial spring force presses the armature plate (5)against the rotor (3)which in turn is pushed against the mounting flange(2). On applying direct current power supply to the coil (9) magnetic field is produced, which pulls the armature plate over the airgap towards the "stator" against the spring force and the rotor is free to rotate and hence brake is released. the brakes are provided with manual hand release assembly and can be used for releasing the brake in case of power failure. description 1. Dust protective ring 2. Flange 3. Rotor 4. Tubular bush 5. Armature plate 6. Compression spring 7. Compression parts 8. Hub 9. Outer pole 10. A- handle b- h.r. Lever c- knob d- h.r. Spring e- h.r. Bolt 11. A- spring washer b- mounting bolt 12. Torque adjustment nut size selection and ordering information approximate necessary torque or size of a unit for applications involving low inertia & low operating frequency is determined as ; torque = [ 9550 x (k.w. / speed)] x safety factor [k] safety factor [k] to ensure necessary transmission safety also under extreme operating conditions adequate safety factor must be considered the value of which depends on operating conditions namely, the type of load, prime mover etc. Typically [k]for electric drive low masses equal loading & non-intermittent operation [2.0] low masses light shock load & intermittent operation [2.5] medium masses, light shock load & intermittent operation [3.0] large masses, light shock load & intermittent operation [3.0] non-overhauling loads [2-3] overhauling loads [3-4] diesel engine drive [4-5] compressor driven [5-6] however, we recommend you to perform detailed calculations for which please consult us. life of friction material the life of the friction liner depends on a number of factors namely, the inertia to be retarded or stopped, the relative speed, the operating frequency, the temperatures at the friction surfaces etc. These brakes must run dry. Oil, grease, foreign materials & other lubricants affect life and characteristics of friction material. electrical connections the brakes are operated with dc. Connection from three phase or ac mains network can be made via a transformer rectifier, bridge rectifier or half wave rectifier. To restrict the high inductive voltage / back emf a suitable supressor and capacitor network is provided across the connector coil as shown in fig.

...more

Single disc clutch

We are manufacturer of Single Disc Clutch and we are an ISO 9000 certified Company. We are also supplier of Single Disc Clutch and we also known for exporter of Single Disc Clutch.

...more

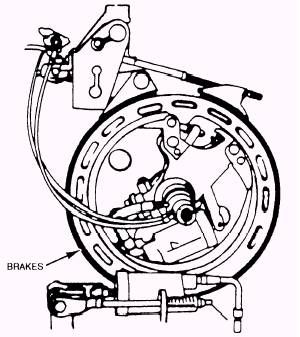

Shoe Types Brakes

Constructional Features: Special constructional features such as those listed below account for exceptionally long mechanical life of the brakes. Neoprene shock absorber - prevents link pin breakage and increases the life of the solenoid. Hardened steel lever and spring gland reduces wear at the pins and all other points of contact. Cast iron wheel - The physical properties of the iron minimize the tendency of the wheel to deposit metal particles in the lining which could result in serious scoring of the wheel. Spring pins - The tight gripping spring pins insure against the loss of pins due to shock. inexpensive lining replacement - Linings attached to shoes by removable flat head groove - pins. Fewer joints- The shoe is actually a part of the shoe lever and not separate from it. This makes fewer mechanical joints and keeps wear points at minimum. Solenoid - The solenoid coil can be removed without disturbing the brake adjustment. Solenoid loading is designed to reduce wear. Adjustments: Adjustments for torque and lining wear are conveniently and quickly made. Braking torque and living wear adjustments are made at the top of the brake. A set screw and locking nut located on the top of the solenoid frame provide adjustment for equalizing clearance between the brake shoes to prevent dragging when the brake is released. Applications: Typical application include conveyors, hoisting equipment, machine tools, printing presses, small cranes, over head doors, vacuum moulding machines etc. Coil Duty Classification: Shunt brake coils are used either for intermittent (1 hour) duty or continuous duty. Intermittent duty indicates that the coil can be placed across the line for one hour without excessive heating. This is equivalent to ½ time continuous duty or one minute on and one minute off. Coil rated for continuous duty can be connected across the line continuously without exceeding temperature limit. The class of insulation of coils is class F. Mounting: Shoe brake is designed and recommended for the use and mounting only in the floor position. Side or vertical mountings are not recommended because the solenoid loading is altered resulting in accelerated and premature coil failure. AC Solenoids: The remarkable efficiency of “GMAC” brand shoe type AC Solenoids (Pull type) encourages application to a wide rang of purposes requiring a definite pull motion under automatic or distant driven machinery. Typical functions include the operation of electro mechanical brakes and valves, various short-stroke motions on machine tools and many operations required in automatic machinery of all kinds. APPLICATION : Used in Machine Tools, Hydro Extactors, Coil winding Machines, Wire Drawing Machines, Rubber Mixing Mills, Rolling Mills, Printing Machines and in many other industries such as a Cement, Mining, Sugar, Textile, Material Handling etc..In case of power failure in machines like Hoists, Cranes, Winches, Elevators, etc.. application of brake is must. We offer AC type brakes, called fail safe brake, as in case of power failure, these brakes apply mechanically. SPECIAL FEATURES : Nylon/Bakelite bobbin with ‘F’ class insulation coil. 10mm thickness E plate / I plate All machines nuts are used. M.S. Plate for liner. 15mm thickness mounting plate. Close type Connector with Nylock Nut. 16.5mm thickness liner. C.R.N.G.O. stamping. Heavy Duty Brake A.C. DISK BRAKES : (FAIL SAFE) Very compact and modern in design. Foundation is not necessary as they are directly mounted on non-driving end shaft of the motor. It consists of liner plates (Brake Disc) with square hole at the center. One corresponding piece of square hub is supplied with the brake. This hub is keyed to the motor shaft and the liner plate is free on this hub. Normally liner plate is gripped between two discs with the help of spring pressure. They work on 230/ 415 Volt A.C. When the current is supplied on the brake, one disc is attracted by electromagnet against pressure and the liner plate is released. Thus the brakes is “off”. Once the brake is set it dose not require adjustment or maintenance. When the liner plates wear with the use then only air gap is required to be maintained periodically. An arrangement to release the brake manually could be provided on request. FAIL SAFE BRAKE FOR BRAKE MOTORS: Brake Motor is combination of three phase Squirrel Cage Induction Motor with Electro-Magnetic Disc Brake (A.C.) When power is switched off with ordinary motor, the rotating part will stopped after some time but if brake motor is used rotating mass will stop instantaneously. All Brakes are mounted at non-driving end of motor, braking disc is mounted directly on motor shaft. Brakes are directly acting, no lever or links are required. Liner plate is only wearing part and this is easily replaceable

...more

Rectifier Diode

We are manufacturer of the widely acclaimed Industrial Rectifiers which are known for its performance centric properties. This product displays great quality and is meant to provide accurate readings. Our Industrial Rectifiers EE044 is used for converting 440 VAC to 190 VDC. We supply diodes and rectifiers of leading brands and trusted manufacturer. We ensure that the quality aspect of this product is not compromised by any chance and henceforth ensure that comprehensive quality checks are done at a regular basis.

Feature : Provides accurate readings,Reliable technology.

...more

Rectifier

We are manufacturer of the widely acclaimed Industrial Rectifiers which are known for its performance centric properties. This product displays great quality and is meant to provide accurate readings. Our Industrial Rectifiers EE022 is used for Converting 230 VAC to 190 VDC. We supply diodes and rectifiers of leading brands and trusted manufacturer. We ensure that the quality aspect of this product is not compromised by any chance and henceforth ensure that comprehensive quality checks are done at a regular basis. Features: Provides accurate readings. Reliable technology. Cost effective.

...more

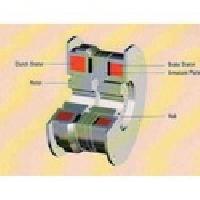

Open Type Clutch Brake Combination

We Offer Open Type Clutch Brake Combination. Salient features: This is an open type clutch brake combination and has no body, flanges, etc. This is a combination of flange mounted clutches and flange mounted brakes and has armature in between which is attracted on either side by clutchbrake magnets.

...more

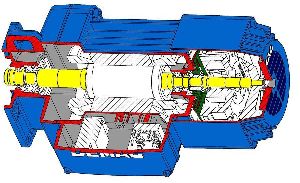

Motor With DC Fail Safe Brakes

We manufacture Foot mounted motors with DC Fail Safe brakes Flange mounted Brakes We also manufacture Flange mounted Brakes with DC Fail Safe Brakes Flange mounted brakes We are supplier of Motor with DC Fail Safe Brakes. Ordering Information : 1. Make of Motor 2. Type of Motor 3. Frame Size 4. Brake Type 5. Brake Size

...more

Motor

Range : Standard 3 Phase Induction Motors with rating 0.12 HP to 10 HR are available from frame size 63 to 160 with standard speed and various construction. Standards : Performance conforms to IS:325 and dimensions according to IS:1231 and IS:2223. Ratings : Motors are rated for continues duty type S1 at an ambient of 40° C and site altitudes of up to 1000 M above mean sea level. Voltage and Frequency :Motors designed are for rated voltage of 415V +/-6%, 3 Phase, 50 Hz +/-3% supply. Motors with special designs of voltage / frequency can be offered on request. Paint : Standard Synthetic enamel paint is provided which is suitable for tropical conditions. However, special paint can be provided on request. Construction : Standard motors with single shaft extension are for horizontal foot mounting (B3 as per IS:1231) and vertical flange/face mounting (B5 & B14 as per IS:2223). Other types of construction as show below can be offered on request. Insulation System : All standard motors are provided with class "B" insulation system. Motors with any other class of Insulation can be offered on request. Degree of Protection : Motors have IP44 degree of protection as a standard feature conforming to IS 4691. Motors can be supplied with protection IP54 as well as IP55 on special request. Cooling & Ventilation : Type of cooling is as per IS 6362. All motors have an external bi-direction centrifugal fan. Terminal Box : All motors are provided with terminal box is on the top of the housing. Terminal box can be rotated in steps of 90°. Noise : Motors are designed for low noise level in accordance with IS 12065. Bearing System : All motors are equipped with pre-lubricated bearing. Regressing facility can be provided on request. Earthing Terminals : Two earthing terminals are provided in all the motors. Both on the stator housing. Terminal can be provided in "T" Box on request. Special Features Available on Request. Mechanical Features : Special Mountings, Shaft Extensions, Key way, Paint, Nameplate designs. Electrical Features : Supply voltage option (160 V to 600 V) Multiple Voltage, Variation in Supply Frequency (60 Hz), Polarity Option (8, 10, 12 Holes) Special Protection (PTC Thermistor) and Insulation (Class H or Other).

...more

industrial rectifiers

We are manufacturer of the widely acclaimed Industrial Rectifiers with VDC which are known for its performance centric properties. This product displays great quality and is meant to provide accurate readings. Our Industrial Rectifiers with VDC is used for converting alternative current (AC) to direct current (DC). We supply diodes and rectifiers of leading brands and trusted manufacturers. We ensure that the quality aspect of this product is not compromised by any chance and henceforth ensure that comprehensive quality checks are done at a regular basis. Features: Provides accurate readings. Reliable technology. Cost effective.

...more

industrial clutches

hoist brakes

We manufacture various types of brakes of Krane Like : Disc Brakes, Single Disc Brakes, Thurston Brakes, Shoe Brakes and Flange mounted brakes. Our motor are ISO 9000 Certified and comes with one year warranty. We Supply our products within 3-4 days of confirmed PO.

...more

Hoist Brake Motors

We specialize in manufacturing, supplying and exporting a desired range of Brake Motor, which is manufactured using premium quality raw material. Hoist Brake Motor, which we offer, complies with various industrial standards for quality and performance. Our offered assortment of motors is manufactured with modern technology by using supreme grade components at well-equipped infrastructure unit.Moreover, these Hoist Brake Motors are easy to install and simpler to maintain.

...more

Geared Motors

These motors are produced from 0.5 HP to 20.0 HP and speed ranging from 1.5 RPM to 450 RPM. They are designed for continuous duty under ardaous operating conditions. These can be supplied as gear units also, where the flange mounted motors procured by customers can be fitted. We also supply inline gearbox with input shaft to which the customer can connect a standard foot mounted electric motor. Our generated motors process high efficiency, low noise operation and sturdy design. Gears :High tensile low alloy steel is used as a raw material. Ample dimensions of gear wheels and shafts ensure long life of gearbox. Gears are designed to transmit high torque and power with smooth running under all types of abnormal operating conditions. Housing and Covers : Closed grain cast iron is the material used for significant loading conditions for gearbox housing and covers. The suave design of housing with partition wall provides it a great amount of torsional rigidity. Ample surface area is provided for heat dissipation. Shaft and Bearings : Adequate bearing spans, sound dimensioning and elaborate desing contribute to the high degree of siffness and resistance to the fatigue and shock loads for the shafts. Bearings are selected such that they ensure longer life, smooth operations for the gear unit and to withstand high overhung loads. Lubrication : Gears are lubricated by splash lubrication of oil. It is provided with an oilseal, oil-leval indicatior, drain plug and breather plug. Geared motors are delivered without oli before starting, oil must be filled up to the level of oil level plug. First oil change must be done after operating 400 hours. Consequent oil changes should be occured after every 5000 hours of operation. Grease packed units are available on request. Testing : All components are thoroughly inspected at various stages and assmbled units are tested on no load for oil leakage, noise level and temperature. The electric motor used in standard geared motors are TEFC squirrel cage induction motors. They are suitable for 415 volts +- 10%, 50 Hz +- 5%. Motors correspond to IP-55 enclosure as per IS-4691. Flame proof and weather proof also can be given on request for special applications. We can also supply out geared motors with special motors such as brake motor, DC motor, multi speed motor, crane duty motor etc

...more

Geared Brake Motors

These can be supplied as gear units also, where the flange mounted motors procured by customers can be fitted. We also supply inline gearbox with input shaft to which the customer can connect a standard foot mounted electric motor.

...more

Foot Mounted Motor

In absence of power the braking torque is generated by several compression springs whose axial spring force presses the armature plate against the rotor which in turn is pushed against the mounting flange. When power to the brake and motor is supplied at the same time brake coil produces strong magnetic field and pulls the A.P. against the compression springs force towards the stator (Brake Coil) over the air gap and rotor becomes free to rotate. The attraction of the A.P. and returning to its original position takes place instantaneously and thus fail safe nature is ensured in case of power failure. Motor can also be supplied with brake Type EFMB and combination Type ECBC.

...more

flange mounted clutch

Flange Mounted Brake

Salient Features Simple Construction Single Plate Dry Type Maintenance free long life Stationary Field (No Slip Ring) Coil with Class 'F' Insulation Simple wear adjustment Special Friction Material High Operating Frequency Simple Installation Working of EFMB When DC Voltage is supplied to the coil(6) the armature (4) is attracted towards the brake liner(5) of the stator(7)and the friction stops the rotating component. When supply is cut off the "prestressed" spring(3) pulls back the armature plate and hence the brake is free Description 1. Flange 2. Rivet 3. Spring 4. Armature Plate 5. Brake Liner 6. Coil 7. Brake Stator Size Selection Ordering Information Approximate necessary Torque or Size of a unit for applications involving low inertia & low operating frequency is determined as ; TORQUE = [ 9550 x (K.W. / SPEED)] x SAFETY FACTOR [K] SAFETY FACTOR [K] To ensure necessary transmission safety also under extreme operating conditions adequate safety factor must be considered the value of which depends on operating conditions namely, the type of load, prime mover etc. Typically [K] For Electric drive Low masses equal loading & non-intermittent operation [2.0] Low masses light shock load & intermittent operation [2.5] Medium masses, light shock load & intermittent operation [3.0] Large masses, light shock load & intermittent operation [3.0] Non-overhauling loads [2-3] Overhauling loads [3-4] Diesel engine drive [4-5] Compressor driven [5-6] However, we recommend you to perform detailed calculations for which please consult us. Life Of Friction Material The life of the friction liner depends on a number of factors namely, the inertia to be retarded or stopped, the relative speed, the operating frequency, the temperatures at the friction surfaces etc. These brakes must run dry. Oil, grease, foreign materials & other lubricants affect life and characteristics of friction material. Electrical Connections The Brakes are operated with DC. connection from three phase or AC mains network can be made via a transformer rectifier, bridge rectifier or half wave rectifier. To restrict the high inductive voltage / back EMF a suitable Supressor and Capacitor network is provided across the connector coil as shown in fig.

...more

Electromagnetic Spring Loaded Fail Safe Brake

We Offer Electromagnetic Spring loaded fail safe brake with electromagnetic & manual release type efsb (normally on). Salient features : Compact robust unit simple wear adjustment High operating frequency with manual release provision Coil with class 'f' insulation All metal parts are rust protected Two friction surfaces Low power requirement We are manufacturer of Electromagnetic Spring Loaded Fail Safe Brake. The braking torque in excel spring loaded fail safe brake is generated by several compression spnngs (6) whose axial spring force presses the armature plate (5)against the rotor (3)which in turn is pushed against the mounting flange(2). On applying direct current power supply to the coil (9) magnetic field is produced, which pulls the armature plate over the airgap towards the "stator" against the spring force and the rotor is free to rotate and hence brake is released. The brakes are provided with manual hand release assembly and can be used for releasing the brake in case of power failure. We are also known for supplier of Electromagnetic Spring Loaded Fail Safe Brake. 1. Dust protective ring 2. Flange 3. Rotor 4. Tubular bush 5. Armature plate 6. . Compression spring 7. Compression parts 8. Hub 9. Outer pole 10. A. Handle b. H. R. Lever c. Knob d. H. R spring e. H. R bolt 11. Spring washer, mounting bolt 12. Torque adjustment nut

...more

Electromagnetic Clutch

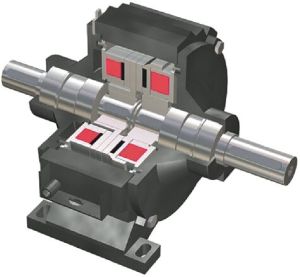

Double Shaft Clutch Brake

Clutch Brake Combination Double Shaft Type ECBC – DS (Encased) Salient Features Ready in assembled form Totally encased unit Strong bearing design Adjustable without dismantling Good heat dissipation through increased surface area Slotted armature for torque stability Working When DC power is supplied to the clutch coil rotor attracts the armature assembly thus transmitting torque from drive connected to input shaft via clutch to load connected through output shaft. When supply is switched off from clutch the drive gets disengaged and simultaneously supply is given to brake coil which stops the output shaft connected to load. Ordering Information : Type Size Voltage Note : 1 Nm = 0.012 Kgm = 0.737 Ib-ft = 10.2 kgcm Keyways to Indian standard / Din Standard. Standard Voltages 24 VDC ; 96 VDC ; 190 VDC ; other voltages on request.

...more

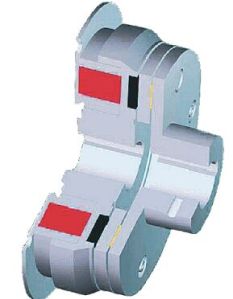

Double Clutch Combination

Working EXCEL double clutch combination consists of two EFMC series clutches in a single housing and a single tandom shaft. EDCC are manufactured considering the higher frequency of forwarding & reversing mechanics. A combination of clutches are used for reversing revolution of the driven member with driving member turning in one direction. Also combination of clutches are used to increase or decrease the speed during operation without stopping the driving member.. Load is being transferred either by the first or second clutch. At a time only one clutch gets engaged while other remains idle. SAFETY FACTOR [K] To ensure necessary transmission safety also under extreme operating conditions adequate safety factor must be considered the value of which depends on operating conditions namely, the type of load, prime mover etc. Typically [K] For Electric drive Low masses equal loading & non-intermittent operation [2.0] Low masses light shock load & intermittent operation [2.5] Medium masses, light shock load & intermittent operation [3.0] Large masses, light shock load & intermittent operation [3.0] Non-overhauling loads [2-3] Overhauling loads [3-4] Diesel engine drive [4-5] Compressor driven [5-6] However, we recommend you to perform detailed calculations for which please consult us. Note : 1 Nm = 0.012 Kgm = 0.737 Ib-ft = 10.2 kgcm Keyways to Indian standard / Din Standard. Standard Voltages 24 VDC ; 96 VDC ; 190 VDC ; other voltages on request. Size Selection And Ordering Information Approximate necessary Torque or Size of a unit for applications involving low inertia & low operating frequency is determined as ; TORQUE = [9550 x (K.W. / SPEED)] x SAFETY FACTOR [K] Ordering Information : Type Type Voltage

...more

Dc Fail Safe Brake

We are manufacturer of dc fail safe brake. The brakes are provided with manual hand release assembly and can be used for releasing the brake in case of power failure. We are also known for supplier of dc fail safe brake. Salient features: • compact robust unit simple wear adjustment • high operating frequency with manual release • all metal parts are rust protected • two friction surfaces • low power requirement

...more

Crane Duty Brake

We Manufacture Hoist Brake Motors in flange and foot mounting. With AC and DC Brakes as per Customer require. Our motor are ISO 9000 Certified and comes with one year warranty. We Supply our products within 3-4 days of confirmed PO

...more

Repairing Services

Be first to Rate

Rate ThisOpening Hours