Waste Water Filter Press

We are one of the leading organization engaged in providing excellent quality Waste Water Filter Press, which are manufactured by using high grade material. These Waste Water Filter Press are widely appreciated by our clients which are situated all round the nation. We are also offering Ceramic Filter Press.

...more

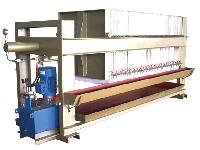

Semi Automatic Filter Press

Avail from us precisely designed, high performance Semi Automatic Filter Press. We design and fabricate Semi Automatic Filter Press by using the latest techniques as per the industry set norms. The Semi Automatic Filter Press, offered by us, has manually controlled operation and requires least maintenance. Semi Automatic Filter Press can be availed at economical price from us. We are a well-known Semi Automatic Filter Press Manufacturer, Exporter and Supplier in Gujarat, India. Highlights Comes with single hydraulic CylinderMaximum number of plates is 100+ Hydraulic cylinder is automatically opened and closedInlet slurry is controlled with a Variable Frequency Drive

...more

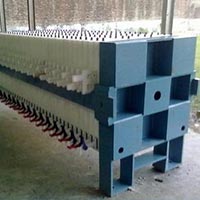

Recessed Chamber Filter Press Plates

we are offering recessed chamber filter press plates. we are counted amid the leading recessed chamber filter press plates manufacturers, exporters and suppliers in gujarat, india. we utilize high-quality polypropylene to make recessed chamber filter press plates. thereby, our recessed chamber filter press plates are highly corrosion resistant and durable; and can be used for almost all kinds of filtration processes requiring normal dry solids filtration. available in gasket and non-gasket stylessizes ranging from 305mm to 1500mm about gaskated and non-gasketed filter plates gaskated filter plates ensure less chance of seepage and non-gaskated type of plate owing to an o-ring seal around the chamber and the filtrate pots. highlights about the plates and frames fabricated from hygienic, light, chemical resistance polypropylenebest suited for basic filtration processeseasy to use no maintenance dependable and efficient in beverage industriesbiochemical applicationschemical processespharmaceutical applicationsblood and plasma applications sizes range : from 610mm to 1200mm advantage of plate & frame v/s chamber plate corner feed plates are widely used owing to their plentiful design advantages for almost every filter press installation. with plate and frame type plates, the most efficient cake formation and solid distribution throughout the plate stack is easily possible. removing a center feed eye enables formation of a sturdy plate requiring no backing stay bosses which impede through cake discharge as well as cake washing.with a recess filter press, cake washing is difficult due to wash water '' short circuiting" through the open center feed eye. corner feed is the only plate design which ensures through cake washing integrity. sizes & style full range of plate sizes and styles recessed chamber plategasketed chamber platenon-gasketed chamber platemembrane / squeeze plateplates and frames5 kg/cm2 to 15kg/cm2 operationscenter feedcorner feedcake thickness up to 50 mmsuitable for any style of filter pre sizes available 470mm x 470mm 610mm x 610mm760mm x 760mm 800mm x 800mm915mm x 915mm 1000mm x 1000mm1200mm x 1200mm round plates : 800 & 610 choice of filter pressure thick and thin webs on chamber plates for 100 psi (7 bar) and 225 psi (15 bar) operations.plates and frames operating up to 100 psi (7 bar) drainage pips advantage excellent cloth supportminimum cloth weargreater plate strengthhigher filtration ratesoptimum cake formationminimum web definition manufacturing process over 15 years of experience in plate molding100 % virgin materials (non pigmented)wide resign selection for special applicationcontinuous development and testing for quality and improvementadvance injection cum compression molding process multiple material choice polypropylene : most application up to 100ocglass reinforced polypropylene : special applicationspvdf : special application up to 120oc

...more

pp recessed filter plates

Catering to the requirements of several industries, we bring forth the precision-engineered PP Recessed Filter Plates. The PP Recessed Filter Plates that we provide are made from the finest polypropylene. The PP Recessed Filter Plates, offered by us, are high in demand as they are highly corrosion resistant and durable. Further, our PP Recessed Filter Plates can be used for virtually all types of filtration processes requiring normal dry solids filtration. Available In Gasket and non-gasket stylesSizes ranging from 305mm to 1500mm About Gaskated And Non-Gasketed Filter Plates Gaskated filter plates ensure less chance of seepage and non-gaskated type of plate owing to an o-ring seal around the chamber and the filtrate pots. Highlights About The Plates And Frames Ideal for basic filtration processesMade from chemical resistance, light, hygienic polypropyleneEasy to handle Maintenance freeReliable and efficient in Chemical processesBiochemical applicationsPharmaceutical applicationsBeverage industriesBlood and plasma applications Sizes Range : From 610mm to 1200mm Advantage Of Plate & Frame V/S Chamber Plate Corner feed plates are widely used owing to their plentiful design advantages for almost every filter press installation.With plate and frame type plates, the most efficient cake formation and solid distribution throughout the plate stack is easily possible. Removing a center feed eye enables formation of a sturdy plate requiring no backing stay bosses which impede through cake discharge as well as cake washing.With a Hydraulic Filter Press Plate, cake washing is difficult due to wash water '' short circuiting" through the open center feed eye. Corner feed is the only plate design which ensures through cake washing integrity. Sizes & Style Full range of Plate Sizes and Styles Recessed chamber plateGasketed chamber plateNon-gasketed chamber plateMembrane / squeeze platePlates and Frames5 kg/cm2 to 15kg/cm2 operationscenter feedcorner feedcake thickness up to 50 mmSuitable for any style of filter press Sizes Available 470mm X 470mm610mm X 610mm760mm X 760mm800mm X 800mm/li>915mm X 915mm1000mm X 1000mm1200mm X 1200mm Round Plates : 800 & 610 Choice Of Filter Pressure Thick and thin webs on chamber plates for 100 psi (7 bar) and 225 psi (15 bar) Operations.Plates and Frames operating up to 100 psi (7 bar) Drainage Pips Advantage Excellent cloth supportMinimum cloth wearGreater plate strengthHigher filtration ratesOptimum cake formationMinimum web definition Manufacturing Process Polypropylene : Most application up to 100oCGlass reinforced Polypropylene : Special applicationsPVDF : Special application up to 120oC

...more

Pp Filter Press

We are engaged in offering a quality range of PP Filter Press to our customers. These PP Filter Press are fabricated using high quality stainless steel and other raw material. Our products are available in various grades and versions. The offered range is quality tested on various parameters.

...more

polypropylene filter plates

We are a prominent filter press plates manufacturer, exporter and supplier in gujarat, india. We provide different types of filter press plates comprising ceramic round filter press plates, pp recessed filter plates and chamber filter press plates. To make these filter press plates, we use the best quality polypropylene. Filter press plates can be availed from us in different sizes. Our filter press plates are reckoned to be best when it comes to corrosion resistance, strength and longevity.

...more

Oil Filter Press

Membrane Filter Press

Clients can avail from us Membrane Filter Press that is made using the latest techniques. Our Membrane Filter Press is acclaimed to diminish the disposal costs or successive processing for Filter Cake. Furthermore, Membrane Filter Presses, offered by us, are high in demand as they efficiently decrease the remaining moisture content. Membrane Filter Press can be purchased at reasonable price from us. We are a well-reckoned Membrane Filter Press Manufacturer, Exporter and Supplier in Gujarat, India. Details Membrane Filter Press is fitted with flexible Membrane PlatePlastic or rubber diaphragm is used to cover the exterior faces of the Membrane Filter Press.Membrane Filter Press operates at a feed pressure of up to 7 bars and squeeze pressure up to 15 bars. Special Membrane Filter Press can be designed for higher feed and squeeze pressure. Advantage of Membrane Filter Press Membrane Filter Press is better as the ordinary filter presses filter only 75 - 80 % of the batch in the first 50 % of the cycle time.If the Plate stock is opened before the full cycle is complete, the result is a wet, sloppy cake.A Membrane Filter Press can be stopped at the most efficient point in its cycle.By applying pressure to the Membrane built in to the Filter Plate, the Cake squeezed to achieve final solid content in considerably reduced cycle time. Design considerations of Membrane Filter Press Filteration pressureFilteration timeSqueezing pressureSqueezing timeThickness of Cake before the squeezing processThickness of Cake after the squeezing processDensity and Cake dryness

...more

Manual Filter Press

We hold expertise in designing Manual Filter Press by utilizing the latest techniques. We provide Manual Filter Press with Ratchet closing Device. Furthermore, the Manual Filter Press that we deal in comprises ratchet mechanism, pinion and gear wheel. Manual Filter Presses can be purchased at market-leading price from us. We are a well-reckoned name as Manual Filter Press Manufacturer, Exporter and Supplier in Gujarat, India. Highlights Manual closing and opening Closing plates are shifted by hand Manual cake dischargeEconomic and efficient

...more

Filter Press Plates

we are offering filter press plates. catering to the requirements of several industries, we bring forth the precision-engineered hydraulic filter press plates. the hydraulic filter press plates that we provide are made from the finest polypropylene. the hydraulic filter press plates, offered by us, are high in demand as they are highly corrosion resistant and durable. further, our hydraulic filter press plates can be used for virtually all types of filtration processes requiring normal dry solids filtration. available in gasket and non-gasket stylessizes ranging from 305mm to 1500mm about gaskated and non-gasketed filter plates gaskated filter plates ensure less chance of seepage and non-gaskated type of plate owing to an o-ring seal around the chamber and the filtrate pots. highlights about the plates and frames ideal for basic filtration processesmade from chemical resistance, light, hygienic polypropyleneeasy to handle maintenance freereliable and efficient in chemical processesbiochemical applicationspharmaceutical applicationsbeverage industriesblood and plasma applications sizes range : from 610mm to 1200mm advantage of plate & frame v/s chamber plate corner feed plates are widely used owing to their plentiful design advantages for almost every filter press installation.with plate and frame type plates, the most efficient cake formation and solid distribution throughout the plate stack is easily possible. removing a center feed eye enables formation of a sturdy plate requiring no backing stay bosses which impede through cake discharge as well as cake washing.with a hydraulic filter press plate, cake washing is difficult due to wash water '' short circuiting" through the open center feed eye. corner feed is the only plate design which ensures through cake washing integrity. sizes & style full range of plate sizes and styles recessed chamber plategasketed chamber platenon-gasketed chamber platemembrane / squeeze plateplates and frames5 kg/cm2 to 15kg/cm2 operationscenter feedcorner feedcake thickness up to 50 mmsuitable for any style of filter press sizes available 470mm x 470mm610mm x 610mm760mm x 760mm800mm x 800mm/li>915mm x 915mm1000mm x 1000mm1200mm x 1200mm round plates : 800 & 610 choice of filter pressure thick and thin webs on chamber plates for 100 psi (7 bar) and 225 psi (15 bar) operations.plates and frames operating up to 100 psi (7 bar) drainage pips advantage excellent cloth supportminimum cloth weargreater plate strengthhigher filtration ratesoptimum cake formationminimum web definition manufacturing process polypropylene : most application up to 100ocglass reinforced polypropylene : special applicationspvdf : special application up to 120oc

Brand Name : Filter Plates

...more

Hydraulic Filter Press

Catering to the requirement of several industries, we bring forth a large gamut of Hydraulic Filter Press. The Hydraulic Filter Press that we provide is user-friendly and requires less maintenance. Further, the opening and closing of Hydraulic Filter Press is done by power pack assembly and hydraulic cylinder. Instead of ratchet pinion locking, hydraulic cylinder is designed for the Filter Press locking. Hydraulic Filter Press can be availed at market-leading price from us. We are a well-recognized Hydraulic Filter Press Manufacturer, Exporter and Supplier in Gujarat, India. Available Types Of Hydraulic Cylinder Locking System Hydraulic Cylinder with mechanical lock nutPull back type Hydraulic cylinder operated by control panel Hydraulic Cylinder Capacity : 30 to 300 mt Stroke - 150 to 1000 mm. Note : Filter Press size depends on overall width and on the number Plates installed. Available In Different Material (Pure Polypropylene)Sizes (470 * 470 mm to 1500 * 1500 mm)Design (Recessed plate)

...more

Fully Automatic Filter Press

We are one of the most sought-after Fully Automatic Filter Press Manufacturers, Exporters and Suppliers in Gujarat, India. We use quality-tested parts and components to manufacture the Fully Automatic Filter Presses. Our Fully Automatic Filter Presses are reckoned to be best in terms of make and performance. The Fully Automatic Filter Press that we provide is available in two different models such as Single Auto Filter Press Comes with single hydraulic CylinderMaximum number of plates is 25PLC (Programmable Logic Control) Based computerized control system automatically doesPlate closingLoad holdingFeeding of slurryPlate openingCake discharge Multi Auto Filter Press 2 to 4 cylinder combination is incorporatedThe plate pack has maximum number of Plates i.e. 60 platesWith a Programmable Logic Control (PLC) Based control system, the filtration cycle is totally automated.

...more

Filter Press

We are offering filter press, it is due to our rich industry experience and expertise that we have been able to bring forward for our clients a durable and reliable range of polypropylene filter press, pp filter press, pp filter press plates. We manufacture the complete range offered by us using optimum quality raw material and components, procured from reputed vendors. Designed and manufactured in different sizes as well as volumes, these are appreciated for features like reliable performance, high efficiency and longer service life. Our range comprises: cast iron filter press membrane filter press recess filter press pp filter press wooden filter press

...more

Chamber Filter Press

We are identified as one of reputed Manufacturers, Exporters & Suppliers of high quality Chamber Filter Press. We supply Chamber Filter Press that is a dewatering device and used for developing the highest cake solid concentration from any mechanical dewatering equipment. Using superior quality raw materials, we offer Chamber Filter Press as per the specifications provided by the clients. Our Chamber Filter Press is highly appreciated in the global market. Salient Features Rugged constructionEasy to maintainDurableMaximum filtration efficiencyCost-effective Applications Oil IndustryChemical IndustryPharmaceutical Industry

...more

Pp Filter Press Plates

We are offering pp filter press plates. Ceramic round filter press plates are ideal for all sorts of filtration processes that require normal dry-solid filtration. To fabricate ceramic round filter press plates, we use the best quality polypropylene. This is the reason why our ceramic round filter press plates are durable and can efficiently resist corrosion. Ceramic round filter press plates can be availed in different sizes and other specifications from us. We are a trusted name as ceramic round filter press plates manufacturer, exporter and supplier in gujarat, india. available in gasket and non-gasketed stylessizes ranging from 305mm to 1500mm about gaskated and non-gasketed filter plates gaskated filter plates ensure less chance of seepage and non-gaskated type of plate owing to an o-ring seal around the chamber and the filtrate pots. Highlights about the plates and frames: easy to handlemade of hygienic, light, chemical resistance polypropylenemaintenance freebest suited for basic filtration processesreliable and efficient in blood and plasma applicationsbiochemical applicationschemical processesbeverage industriespharmaceutical applications sizes range : from 610mm to 1200mm advantage of plate & frame v/s chamber plate with plate and frame type plates, the most efficient cake formation and solid distribution throughout the plate stack is easily possible.corner feed is the only plate design which ensures through cake washing integrity.with ceramic round filter press plates, cake washing is difficult due to wash water '' short circuiting" through the open center feed eye.removing a center feed eye enables formation of a sturdy plate requiring no backing stay bosses which impede through cake discharge as well as cake washing.corner feed plates are widely used owing to their plentiful design advantages for almost every filter press installation. Sizes & style full range of plate sizes and styles recessed chamber plategasketed chamber platenon-gasketed chamber platemembrane / squeeze plateplates and frames5 kg/cm2 to 15kg/cm2 operationscenter feedcorner feedcake thickness up to 50 mmsuitable for any style of filter press sizes available 470mm x 470mm 610mm x 610mm760mm x 760mm 800mm x 800mm915mm x 915mm 1000mm x 1000mm1200mm x 1200mm round plates : 800 & 610 choice of filter pressure thick and thin webs on chamber plates for 100 psi (7 bar) and 225 psi (15 bar) operations.plates and frames operating up to 100 psi (7 bar) drainage pips advantage excellent cloth supportminimum cloth weargreater plate strengthhigher filtration ratesoptimum cake formationminimum web definition manufacturing process over 15 years of experience in plate molding100 % virgin materials (non pigmented)wide resign selection for special applicationcontinuous development and testing for quality and improvementadvance injection cum compression molding process multiple material choice polypropylene : most application up to 100ocglass reinforced polypropylene : special applicationspvdf : special application up to 120oc

...more

ceramic round filter press plates

Ceramic Round Filter Press Plates are ideal for all sorts of filtration processes that require normal dry-solid filtration. To fabricate Ceramic Round Filter Press Plates, we use the best quality polypropylene. This is the reason why our Ceramic Round Filter Press Plates are durable and can efficiently resist corrosion. Ceramic Round Filter Press Plates can be availed in different sizes and other specifications from us. We are a trusted name as Ceramic Round Filter Press Plates Manufacturer, Exporter and Supplier in Gujarat, India. Available In Gasket and non-gasketed stylesSizes ranging from 305mm to 1500mm About Gaskated And Non-Gasketed Filter Plates Gaskated filter plates ensure less chance of seepage and non-gaskated type of plate owing to an o-ring seal around the chamber and the filtrate pots. Highlights About The Plates And Frames: Easy to handleMade of hygienic, light, chemical resistance polypropyleneMaintenance freeBest suited for basic filtration processesReliable and efficient in Blood and plasma applicationsBiochemical applicationsChemical processesBeverage industriesPharmaceutical applications Sizes Range : From 610mm to 1200mm Advantage Of Plate & Frame V/S Chamber Plate With plate and frame type plates, the most efficient cake formation and solid distribution throughout the plate stack is easily possible.Corner feed is the only plate design which ensures through cake washing integrity.With Ceramic Round Filter Press Plates, cake washing is difficult due to wash water '' short circuiting" through the open center feed eye.Removing a center feed eye enables formation of a sturdy plate requiring no backing stay bosses which impede through cake discharge as well as cake washing.Corner feed plates are widely used owing to their plentiful design advantages for almost every filter press installation. Sizes & Style Full range of Plate Sizes and Styles Recessed chamber plateGasketed chamber plateNon-gasketed chamber plateMembrane / squeeze platePlates and Frames5 kg/cm2 to 15kg/cm2 operationscenter feedcorner feedcake thickness up to 50 mmSuitable for any style of filter press Sizes Available 470mm X 470mm 610mm X 610mm760mm X 760mm 800mm X 800mm915mm X 915mm 1000mm X 1000mm1200mm X 1200mm Round Plates : 800 & 610 Choice Of Filter Pressure Thick and thin webs on chamber plates for 100 psi (7 bar) and 225 psi (15 bar) Operations.Plates and Frames operating up to 100 psi (7 bar) Drainage Pips Advantage Excellent cloth supportMinimum cloth wearGreater plate strengthHigher filtration ratesOptimum cake formationMinimum web definition Manufacturing Process Over 15 years of experience in plate molding100 % Virgin materials (Non pigmented)wide resign selection for special applicationcontinuous development and testing for quality and improvementadvance injection cum compression molding process Multiple Material Choice Polypropylene : Most application up to 100oCGlass reinforced Polypropylene : Special applicationsPVDF : Special application up to 120oC

...more

Cast Iron Filter Press

We are involved in providing Cast Iron Filter Press. These are fabricated using quality basic material and known for features like reliable performance, high efficiency and longer service life. These filter presses are also available in different sizes as well as volumes and hence meet the various requirements of our clients.

...more

Auto Plate Shifter Filter Press

We hold expertise in designing auto plate shifter filter press by utilizing the latest techniques. We provide manual filter press with ratchet closing device. Furthermore, the manual filter press that we deal in comprises ratchet mechanism, pinion and gear wheel.

...more

chamber filter press plates

We are counted amid the leading Chamber Filter Press Plates Manufacturers, Exporters and Suppliers in Gujarat, India. We utilize high-quality polypropylene to make Chamber Filter Press Plates. Thereby, our Chamber Filter Press Plates are highly corrosion resistant and durable; and can be used for almost all kinds of filtration processes requiring normal dry solids filtration. Available In Gasket and non-gasket stylesSizes ranging from 305mm to 1500mm About Gaskated And Non-Gasketed Filter Plates Gaskated filter plates ensure less chance of seepage and non-gaskated type of plate owing to an o-ring seal around the chamber and the filtrate pots. Highlights About The Plates And Frames Fabricated from hygienic, light, chemical resistance polypropyleneBest suited for basic filtration processesEasy to use No maintenance Dependable and efficient in Beverage industriesBiochemical applicationsChemical processesPharmaceutical applicationsBlood and plasma applications Sizes Range : From 610mm to 1200mm Advantage Of Plate & Frame V/S Chamber Plate Corner feed plates are widely used owing to their plentiful design advantages for almost every filter press installation. With plate and frame type plates, the most efficient cake formation and solid distribution throughout the plate stack is easily possible. Removing a center feed eye enables formation of a sturdy plate requiring no backing stay bosses which impede through cake discharge as well as cake washing.With a recess filter press, cake washing is difficult due to wash water '' short circuiting" through the open center feed eye. Corner feed is the only plate design which ensures through cake washing integrity. Sizes & Style Full range of Plate Sizes and Styles Recessed chamber plateGasketed chamber plateNon-gasketed chamber plateMembrane / squeeze platePlates and Frames5 kg/cm2 to 15kg/cm2 operationscenter feedcorner feedcake thickness up to 50 mmSuitable for any style of filter pre Sizes Available 470mm X 470mm 610mm X 610mm760mm X 760mm 800mm X 800mm915mm X 915mm 1000mm X 1000mm1200mm X 1200mm Round Plates : 800 & 610 Choice Of Filter Pressure Thick and thin webs on chamber plates for 100 psi (7 bar) and 225 psi (15 bar) Operations.Plates and Frames operating up to 100 psi (7 bar) Drainage Pips Advantage Excellent cloth supportMinimum cloth wearGreater plate strengthHigher filtration ratesOptimum cake formationMinimum web definition Manufacturing Process Over 15 years of experience in plate molding100 % Virgin materials (Non pigmented)wide resign selection for special applicationcontinuous development and testing for quality and improvementadvance injection cum compression molding process Multiple Material Choice Polypropylene : Most application up to 100oCGlass reinforced Polypropylene : Special applicationsPVDF : Special application up to 120oC

...more

Filter Presses

Industrial Filter Press

PP Filter Plates

single auto filter press

ETP Plant Filter Press

Be first to Rate

Rate ThisOpening Hours