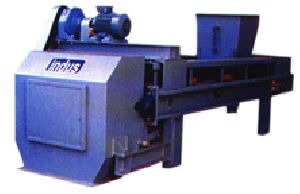

Weigh Feeder

Indus manufactures Electronic Gravimetric Weigh Feeders incorporating state-of-the –art technology for continuous bulk proportioning of solids.The material to be proportionally fed is passed over the belt; flow rate (also cumulative value) of the material is measured and compared with set parameters of the PLC/PID controller. The deviation is corrected by regulating the speed of the conveyor through variable speed A.C.Drive. (closed loop control system)Two high precision load cells are used to measure the belt load & a rotary encoder used to measure speed of the conveyor.Salient featuresPrecision machined rollers used to provide perfect belt run & high accuracyRubber coated pulleys prevents belt slippage.Gravity takes up to ensure constant belt tensionScrappers to prevent belt damage & tare changesEasy maintenance - belt change without aids from sideFully automatic Zero/Span calibrationHighly reliable PLC (with in built PID algorithm) & variable speed AC driveHigh precision load cells with damping to obtain best results.Empty Belt Correction Factor to achieve best AccuracySet Points Programmable from local panel or Main PanelOption FeaturesRs 485 Interface can generate printout with SQC AnalysisApplications Cement, Sponge Iron, Steel, Fertilizer, Chemical, Tobacco & Petrochemical Industries.

...more

Tank Weighing Systems

ndus Hopper/Tank weighing systems are highly rugged & reliable. The Hopper or tank rests on 3 or 4 Loadcells. These Load cells are terminated parallel in to a Junction box. The output signal from J.B is in turn connected to the Signal transmitter/Weight Display Unit. Features: Loadcells with Ip67/Ip68 protectionLoad cell mounting kit with Jack Bolt arrangement for easy removal of load cells.Mounting kit in SS option also available.Loadcells for Agitator based tanks available.Flame Proof systems available.

...more

Nett Weigher

ndus Bag Filling Machine are rugged, accurate and user friendly. These Machines are very simple to operate. The operator feeds the quantity of material to be bagged through the keyboard of the controller. The bag is placed on the discharge chute and start button pressed. The bag gets clamped and immediately preweighed quantity of material is filled into the bag, and the bag is decamped and moves on to the stitching conveyor. Applications:- Rice, Sugar, Dal, Cattle Feed, Chemicals, Minerals, Fertilizers etc.

Resolution : 5gm

Accuracy : ±20gms

Speed : 5-6 bags/min

Features : Cumulative totalizer batch totalizer To set target No. of bags to be filled.

...more

Weigh Belt Feeder

Indus continuous loss in weight feeder provides unparallel versatility in handling wide range of feeding requirements. Feed rate from 50kgs to 1000 kgs per hour can be accomplished with high accuracies. Control of the feeder is through a highly reliable PLC based controller equipped with noise/Vibration elimination technology. Weight measurement is done through highly accurate/sensitive Loadcells. Various models of loss in weight Feeders are available based on the material Characteristics (Flow Properties).a. Twin screw loss in weight feeder.b. Single screw loss in weight feeder.c. Vibratory loss in weight feeder.

...more

Liquid Filling Machine

Indus Liquid filling machine is very simple to operate:Just place the container on the platform, set the target value as required. Now press start push button, the system automatically tares the weight of the container and filling starts. The moment the target weight is achieved, the filling operation stops Application:-Chemical, Pharmaceutical, Edible Oil, Paints, Lubricant & Food products

Working Capacity : 0-30kgs

Air Pressure : 5-6 bar filtered regulated air

Specialities : Facility to view cumulative & batch totalizer value Facility to program target no. of fills. No tin no fill Auto weigh correction

...more

Jumbo Bag Filling Machine

The big bag filling machine has been designed to fill even the most difficult to handle materials,using a time proven technique which involves high precision weighing coupled with a truncated pyramid table with vibrators, the filled material is weighed deaerated and densified before leaving the filling station. The ultimate goal is to produce bags that are stable, stackable, safe & easy to handle.Empty bags are mounted by hanging the four loops of the bulk bags on the suspended weigh frames easy to reach posts. The inlet spout is secured to the flared end of the filling head by a slip ring seal. The slip ring allows proper positioning of the liner when used. The bag is then inflated and the weight is tared. The electronics has a inbuilt timer- the duration of inflation is time settable.The filling cycle is controlled by the microcontroller for fast and efficient filling. The set points programmed included the target weight, fast/dribble feed, table up / down, no of cycles, vibration on time etc.Once filling and densification is complete the bag’s inlet spout is released from the filling head and tied off. The bulk bag is dismounted from the machine with a fork lift by simply driving under the pallet / bag,lifting it and backing out. The filling system can be complete with a up stream delivery device and the control system.The filling spout is concentric with 2 nozzles for AIR purging & aspiration systems. Various quantities like 200,500,750 & 1000 kgs can be filled in one cycle The jumbo bag filling machines are custom designed, the machines can be provided with a roller conveyor underneath, once the filling is complete, the bag is lowered onto the roller conveyor & then the conveyor is switched on & thereby moving the bag out of the machine.The jumbo bag which is placed on the pallet can be shifted by using a fork lift. The bag sizes are chosen based on bulk density of the material. Normal bag sizes are 900 x 900 x 1200 mm or 900 x 900 x 1400 mm. the bags are of HDPE material, with plastic liner inside.

...more

chlorine tonner weighing system

Bg Bag Filling Machine

The big bag filling machine has been designed to fill even the most difficult to handle materials,using a time proven technique which involves high precision weighing coupled with a truncated pyramid table with vibrators, the filled material is weighed deaerated and densified before leaving the filling station. The ultimate goal is to produce bags that are stable, stackable, safe & easy to handle. Empty bags are mounted by hanging the four loops of the bulk bags on the suspended weigh frames easy to reach posts. The inlet spout is secured to the flared end of the filling head by a slip ring seal. The slip ring allows proper positioning of the liner when used. The bag is then inflated and the weight is tared. The electronics has a inbuilt timer- the duration of inflation is time settable.The filling cycle is controlled by the microcontroller for fast and efficient filling. The set points programmed included the target weight, fastdribble feed, table up down, no of cycles, vibration on time etc.Once filling and densification is complete the bag’s inlet spout is released from the filling head and tied off. The bulk bag is dismounted from the machine with a fork lift by simply driving under the pallet bag,lifting it and backing out. The filling system can be complete with a up stream delivery device and the control system.The filling spout is concentric with 2 nozzles for AIR purging & aspiration systems. jumbo_Bag_filling1

...more

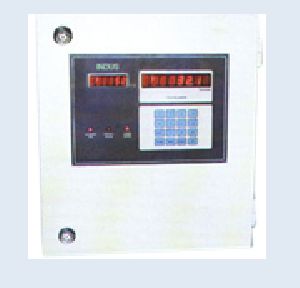

belt weighers

INDUS BELT WEIGHERS are reliable, accurate & durable even in the most demanding industrial application.The belt scale is an industrial equipment which measures the rate of flow and total quantity of material being passed over the scale in a time period. The load being transferred to the belt is sensed by 4 high precision loadcells & the speed is sensed by an Incremental optical encoder (Tacho Generator). These two signals are multiplied digitally at the microcontroller based panel. The load per unit length multiplied by speed of the belt gives the rate of flow while the Rate integrated over time gives the totalized value of material passed over the belt. Displays totaliser weight, flow rate Two nos 4—20 ma output Built in diagnostics Digital calibration for weight Digital calibration for speed Easy to install [minimum down time] Batch control functions [set points] Battery backup memory safeguards against data loss Capacity: 5 TPH TO 1000 TPH)[Can be customized] Power supply: 230 V AC ±10 % 50hz

...more

Belt Weigher

INDUS BELT WEIGHERS are reliable, accurate & durable even in the most demanding industrial application. The belt scale is an industrial equipment which measures the rate of flow and total quantity of material being passed over the scale in a time period. The load being transferred to the belt is sensed by 4 high precision loadcells & the speed is sensed by an Incremental optical encoder (Tacho Generator). These two signals are multiplied digitally at the microcontroller based panel. The load per unit length multiplied by speed of the belt gives the rate of flow while the Rate integrated over time gives the totalized value of material passed over the belt.

...more

Bag filling Machines

The jumbo bag filling machines are custom designed, the machines can be provided with a roller conveyor underneath, once the filling is complete, the bag is lowered onto the roller conveyor & then the conveyor is switched on & thereby moving the bag out of the machine.

...more

Augur Filling Machine with continous band sealer

Indus make Augur Filling Machine is ideal for powder non free flowing materials. The Hopper and the machined screws are constructed in SS304 Material. On start command the Augur is switched on and filling of material in to the weigh hopper commences. The moment 90% of the target value is reached the Augur speed is reduced through VFD. On achieving 100% weight the Augur is switched off. The weighed material is discharged through the funnel.Application: Maida, Atta, Chemical powder,etc..

...more

form fill seal machines

weigh bridge products

Be first to Rate

Rate ThisOpening Hours