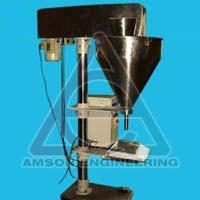

Weighmetric Powder Filling Machine

Thanks to our excellence at meeting customer needs, we have positioned ourselves as a prime Manufacturer, Exporter & Supplier in the industry. We offer Weighmetric Powder Filling Machine in a wide range of designs and specifications to choose from. Our outstanding quality team runs various quality tests to make sure we exceed the quality standards. These quality checks make certain its durability, fine finish and impeccable quality. Structure and Working : Powder filler is made strong and vibration free by its specially designed Pillar structure. This is made from Mild steel ROUND Pipe section of good thickness Hard chrome Plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the Augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a Bearing housing holds and rotates freely when the machine is operated. A stirrer blade provided separately which is operated independently over the driven shaft. The driven shaft is holding an accurately machined stainless steel AUGUR which performs the filling inside the Nozzle. The lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The agitation blade, generally separately driven and controlled, rotates in the opposite direction to the auger breaking any bridge that tends to form in non-free flowing powders. The agitation blade extends right down to the throat of the funnel preventing rat-holing and cavitation and ensuring that the flights are fully filled. The start/stop signals to the auger drive control the pre-set weight in Weigh metric fillers. Technical Specifications Afae1000 Machine size - 1000 L X 700W X 2100mm height. Drive Motor - 1 HP 230VAC 50Hz, 1440 rpm. with VFD(Variable Frequency Drive) Power - 220VAC 50Hz Single Phase Stirrer motor - 1 Hp 32RPM 230VAC Worm Geared Electromagnetic Clutch- Brake - HSCBC 100, 24 VAC Cryotron Make All material contact parts in S.S. 304 Stainless steel 304 Augur (Screw) type filling. Hopper size - 40 Litres (S.S 304), 18 Gauge, mirror finish for AFAE1000 Fill capacity - 50-1000 gms at a time as per set time, Weigh balance - Maximum load capacity - 3 Kgs. Maximum Fill capacity - 1000gms, as per set weight on weigh balance.(easily settable) Output - 15 fills per minute Additional features : Augur Based filling equipped with digital Weigh balance (load cell). One touch Start by a foot-switch Drive through electro-magnetic clutch brake system to get high accuracy filling. High output and increased efficiency. Slow speed geared motor attached to stirrer helps to feed augur uniformly Output of 15 fills/minute can be achieved. High Accuracy up-to +/- 0.5% of fill volume. Low maintenance needed in this model.

Weight : 100-500kg

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Feature : Easy To Operate, Long Life

Warranty : 1year

...more

Weigh Filling Machine

1 Piece(s) (MOQ)

We are offering weigh filling machine. Powder filling machines come in a wide variety of sizes, shapes, filling principles and degrees of technical sophistication in response to the ever-widening diversity of powder filling applications around. Amson’s powder filling machine is specially designed to get high accuracy outputs of powder in a limited time and thereby increase the production. For this achievement, we use digital timing mechanism assisted filling to get perfect accurate fills each time. We designed a model, where the wastage is theoretically nil and the accuracy is maximum. Hygienic and gmp standard parts assures safety for fast contaminating products. any free flowing material, or comparatively free flowing material like flour, spice powder chemical powder, toner powder, talcum, food ingredients, food colouring agents,agro products, masala and other pharma and chemical powders can be filled very accurately by using this machine model. Accuracy this filler is very much high up to +- 1% accuracy in each filling. Speed of filling is also high, since we provide auto option for intermittent filling. The principle of the vertical auger powder filling machine is very simple. Augur rotation creates forward movement of the material with its flights towards the filling nozzle. Each thread (flight) has a particular volume powder holding capacity as per material density. When the screw rotates, powder is taken by the screw and according to the direction of movement; it discharges the powder to the nozzle to the container or pouches. the basic filling head comprises five primary components: 1. s.s hopper containing the powder to be dosed 2. augur or screw rotating vertically through the hopper. 3. funnel or tube outlet to hopper through which the lower parallel part of the auger doses. 4. auger (screw) drive. 5. agitation blade (stirrer) to assist powder feed properly into the flights of the augur. structure and working: powder filler is made strong and vibration free by its specially designed pillar structure. This is made from mild steel round pipe section of good thickness hard chrome plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a bearing housing holds and rotates freely when the machine is operated. A stirrer blade provided separately which is operated independently over the driven shaft. The driven shaft is holding an accurately machined stainless steel augur which performs the filling inside the nozzle. The lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The agitation blade, generally separately driven and controlled, rotates in the opposite direction to the auger breaking any bridge that tends to form in non-free flowing powders. The agitation blade extends right down to the throat of the funnel preventing rat-holing and cavitations and ensuring that the flights are fully filled. The startstop signals to the auger drive control the pre-set weight in weigh metric fillers. technical specifications afae1000: machine size: 1050 l x 700w x 2000mm height. machine model: afae1000- weigh based drive motor: 1 hp 230vac 50hz, 1440 rpm. With vfd(variable frequency drive) power : 230vac 50hz single phase stirrer motor: 1 hp 32rpm 230vac worm geared electromagnetic clutch- brake: hscbc 100, 24 vac cryotron make load cell capacity: 3 kg, 100mg. all material contact parts in s.s. 304 stainless steel 304 augur ( screw) type filling. hopper size 45 liters (s.s 304), 18 gauge, mirror finish for afae1000 fill capacity: 50-1000 gms at a time as per set time, additional features: • augur based filling equipped with digital weighing unit. • one touch start by a foot-switch • drive through electro-magnetic clutch brake system to get high accuracy filling. • high output and increased efficiency. • slow speed geared motor attached to stirrer helps to feed augur uniformly • output of 15- 20 fillsminute can be achieved. • high accuracy up-to +- 0.5% of fill volume. • low maintenance needed in this model.

...more

Volumetric Powder Filling Machine

1 Piece(s) (MOQ)

We are offering volumetric powder filling machine. volumetric powder filling machines come in a wide variety of sizes, shapes, filling principles and degrees of technical sophistication in response to the ever-widening diversity of powder filling applications around. Amson’s augur filling machine is specially designed to get high accuracy outputs of powder in a limited time and thereby increase the production. For this achievement, we use digital timing mechanism assisted filling to get perfect accurate fills each time. We designed a model, where the wastage is theoretically nil and the accuracy is maximum. Hygienic and gmp standard parts assures safety for fast contaminating products. any free flowing material, or comparatively free flowing material like flour, spice powder chemical powder, toner powder, talcum, food ingredients, food colouring agents,agro products, masala and other pharma and chemical powders can be filled very accurately by using this machine model. Accuracy this filler is very much high up to +- 1% accuracy in each filling. Speed of filling is also high, since we provide auto option for intermittent filling. the principle of the vertical auger powder filling machine is very simple. Augur rotation creates forward movement of the material with its flights towards the filling nozzle. Each thread (flight) has a particular volume powder holding capacity as per material density. When the screw rotates, powder is taken by the screw and according to the direction of movement; it discharges the powder to the nozzle to the container or pouches. the basic filling head comprises five primary components: 1. s.s hopper containing the powder to be dosed 2. augur or screw rotating vertically through the hopper. 3. funnel or tube outlet to hopper through which the lower parallel part of the auger doses. 4. augur (screw) drive. 5. agitation blade (stirrer) to assist powder feed properly into the flights of the augur. structure and working: augur filler is made strong and vibration free by its specially designed pillar structure. This is made from mild steel round pipe section of good thickness hard chrome plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a bearing housing holds and rotates freely when the machine is operated. A stirrer blade provided separately which is operated independently over the driven shaft. The driven shaft is holding an accurately machined stainless steel augur which performs the filling inside the nozzle. the lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The agitation blade, generally separately driven and controlled, rotates in the opposite direction to the auger breaking any bridge that tends to form in non-free flowing powders. The agitation blade extends right down to the throat of the funnel preventing rat-holing and cavitations and ensuring that the flights are fully filled. The startstop signals to the auger drive, control the pre-set weight in weigh metric fillers. technical specifications afae500: machine size: 1050 l x 700w x 1950mm height. drive motor :1 hp 230vac 50hz, 1440 rpm. With vfd(variable frequency drive) power : 230vac 50hz single phase stirrer motor: 12 hp 30rpm 230vac worm geared electromagnetic clutch- brake: hscbc 100, 24 vac cryotron make all material contact parts in s.s. 304 stainless steel 304 augur ( screw) type filling. hopper size 45 litres (s.s 304), 18 gauge, mirror finish for afae500 fill capacity: 50-500 gms at a time as per set time, additional features: • augur based filling equipped with digital timer. • one touch start by a foot-switch • drive through electro-magnetic clutch brake system to get high accuracy filling. • high output and increased efficiency. • slow speed geared motor attached to stirrer helps to feed augur uniformly • output of 20-25 fillsminute can be achieved. • high accuracy up-to +- 0.5% of fill volume. • low maintenance needed in this model .

Brand Name : AMSON

...more

Volumetric Filling Machine

As an eminent enterprise, we Manufacturer, Exporter & Supplier offer Volumetric Filling Machine. Moreover, our provided machine is available at cost effective prices. It is widely applauded and cherished because of its longer life and optimum design. For manufacturing it, we make use of only the first-rate raw material. A team of qualified experts strictly matches the quality to industrial quality standards to ensure there is no drop in the quality. Structure and Working : Augur filler is made strong and vibration free by its specially designed Pillar structure. This is made from Mild steel ROUND Pipe section of good thickness Hard chrome Plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the Augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a Bearing housing holds and rotates freely when the machine is operated. A stirrer blade provided separately which is operated independently over the driven shaft. The driven shaft is holding an accurately machined stainless steel AUGUR which performs the filling inside the Nozzle. The lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The agitation blade, generally separately driven and controlled, rotates in the opposite direction to the auger breaking any bridge that tends to form in non-free flowing powders. The agitation blade extends right down to the throat of the funnel preventing rat-holing and cavitation and ensuring that the flights are fully filled. The start/stop signals to the auger drive control the pre-set weight in Weigh metric fillers. Technical Specifications Afae1000 Machine size - 1000 L X 700W X 2100mm height. Drive Motor - 1 HP 230VAC 50Hz, 1440 rpm. with VFD(Variable Frequency Drive) Power - 220VAC 50Hz Single Phase Stirrer motor - 1 Hp 32RPM 230VAC Worm Geared Electromagnetic Clutch- Brake - HSCBC 100, 24 VAC Cryotron Make All material contact parts in S.S. 304 Stainless steel 304 Augur (Screw) type filling. Hopper size - 40 Litres (S.S 304), 18 Gauge, mirror finish for AFAE1000 Fill capacity - 50-1000 gms at a time as per set time, Weigh balance - Maximum load capacity - 3 Kgs. Maximum Fill capacity - 1000gms, as per set weight on weigh balance.(easily settable) Output - 15 fills per minute Additional features : Augur Based filling equipped with digital Weigh balance (load cell). One touch Start by a foot-switch Drive through electro-magnetic clutch brake system to get high accuracy filling. High output and increased efficiency. Slow speed geared motor attached to stirrer helps to feed augur uniformly Output of 15 fills/minute can be achieved. High Accuracy up-to +/- 0.5% of fill volume. Low maintenance needed in this model.

Weight : 100-1000kg

Color : Silver

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Power : 1-3kw

Warranty : 1year

Driven Type : Electric

...more

vibratory sifter

We, being a prime Manufacturer, Exporter & Supplier in the industry, offer Vibratory Sifters. These are craved for by our customers. We ensure to deliver within stipulated time frame. The striking features of this product are effectiveness and durability. The quality on offer is in compliance with the industry quality requirements. We offer this range to our customers at market leading prices. Additional Information : Vibratory sifters comes in various models which are used for sorting powder based on granular sizes or mesh sizes. These units used in various industries where powder product are used directly or as raw materials. The multi track machines are capable for sorting different granule sizes at a time. But, to sift powder in to a single mesh size is the commonly used machine in many industries. The machine is very simple to operate and the productivity is also very high. The sizes of product hopper/ vessel depends upon the production required. There are sizes of 6 kg, 10kg, 15kgs, 25kgs, and 50 kgs and above are available from us. The body of machine can be powder coated or stainless steel as per customer specifications. The machine consists of a base frame over which there is a stainless steel vessel with 3 parts are used. Top barrel shaped vessel, middle with stainless steel wire mesh of required mesh size, and bottom conical vessel to concentrate the powder to center. There is a heavy duty vibro motor is attached at the outer wall of barrel shaped vessel. This produces vibration of the vessel during sifting. The whole top side unit are attached over 4 springs to balance and vibrate. There is a control switch and control knob provided with the unit to start – stop and speed control. The product to be sifted is put in to the vessel from the top and the top lid can be closed where fluffy products are sifted. With the simple switch the sifting can be started. Each batch can be completed in 5 to 10 minutes depends on the property of material to be sifted. The speed of sifter can be changed as per the product. Technical Specifications : Machine Name - Stainless steel Vibratory Sifter MOC - SS 304, sheet metal, Square pipe sections fabricated Vessel capacity - 15 kgs.(30 liters) Power Supply - Single Phase 230VAC Machine Size - 2 (feet) × 2 feet (W) × 4 feet (H) Vibratory Motor - 1/4 HP rotary Vibro motor (SAIDEEP MAKE). Power Consumption - 0.5 KW Features Economic model Adjustable Speed. High output capacity.

Material : Stainless Steel

Application : Industrial

Finishing : Polished

Feature : Durable

...more

vacuum filling machines

1 Piece(s) (MOQ)

We manufacture a versatile filling machine for volume filling applications. The machine is called vacuumetric filler. Very useful filling machine designed for alcohol, perfumes, and distillery industries. Here, the machine works on the basis of vacuum suction from the container. Fast filling of any glass bottles can be done by using this machine. Various volumes can be filled by adjusting the height of bottle holder and by adjusting the vacuum filling nozzle. Machine structure and working: complete machine frame is made from mild steel angle structure, welded, and finished with polymer. Total frame structure is covered by stainless steel sheet metal of good gauge and finish. A ¼ hp 230vac oil cooled vacuum pump is providing the vacuum required during filling. This unit is mounted inside the frame with cover, so that the noise is maintained to a minimum during working. all the other parts like, liquid overflow trap, fill nozzles, are mounted over the frame structure. All material contact parts are made from stainless steel 304 qualities or 316 material as per specifications. A trap vessel with suitable capacity is mounted at one side of the top to collect the overflow liquid from the bottles. Fill nozzles are comes in pairs like, 2, 4 as per fill requirement. Various fill volumes can be filled at a time as per adjustment. Also, the fill nozzles are capable to tilt to upto 90 degrees for easy filling. Machine is easy to operate. The glass bottle to be filled is to be pressed towards the fill nozzle, where a gasket is provided. When the bottle is vacuumised, the liquid is filled fast into it. The fill level is maintained as per the nozzle height adjustment inside the bottle. No maintenance is required since, there is no moving parts is involved. Most economical for level filling applications.

...more

Two Head Automatic Linear Piston Filling Machine

To cater to the customers’ needs with excellence, we are engaged in offering Two Head Automatic Linear Piston Filling Machine. As a leading Manufacturer, Exporter & Supplier, we offer a premium quality range. The machine is made of top drawer raw material. Its accurate design, durability and high performance make it an irresistible proposition for the customers. For our esteemed customers, we make it available at easy on the pocket rates. Additional Information : This Automatic Two Head Linear Piston type Filling machine (AEAFC0230) is manufactured only with the purpose of multiplying the output of any filling unit, where the requirement of products is very high. A very reliable machine with low maintenance is the main motto of ours during the design of this machine. The result was a great success and satisfied our customers to the maximum. High efficient machine parts and good technology makes this machine the perfect engine to deliver the best. Any hot or cold liquids/viscous or creamy products can be accurately measured and filled in any shaped containers or bottles with this machine. High output is the result. We are assuring an output of maximum 40 fills per minute with this 2 head machine. Feeding of bottles into the conveyor is done manually and all other operations such as bottle stopping at filling station, Filling of balm accurately and moving the bottles to the outlet side are Automatically done. Specifications for Automatic 2 Head Pneumatic Piston Type Balm Filler Machine Name - Automatic Balm Filling Machine Two Head Pneumatically Operated MODEL - AEABF0230 Machine size - 6 feet L X 3 feet W X 5 feet height . Total machine height - 5 feet including Hopper Machine weight - 185 Kgs approx. Conveyor motor - 1/2 Hp Variable speed AC Motor 3 phase. Power Consumption - 3 KwH.Maximum. Air Consumption -3 cfm.( 2HP Twin Cylinder Air Compressor) Pneumatic Piston type Balm Filling, with adjustable volume Two Head Fill range - 1 gms/ml - 30gms/ml each.(2 Heads) Fill accuracy - +/- 0.5 %. Output - 40 Fills per minute Maximum as per volume. Container/ Bottle Feeding - Manual All material contact parts, Cover, Frame cover are in S.S.304 quality Mat finish. Stainless steel 304 piston barrel type filling - 2 Heads. Bottle stopping for Filling by pneumatic Stoppers - 2 Nos. Panel box at the Bottom of the main assembly with Electrical switches, Pneumatic Solenoid Valves and control units. Separate Operating Panel Board Provided.

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

Warranty : 1year

...more

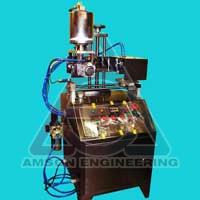

Twist Capping Machine

1 Piece(s) (MOQ)

We are offering twist capping machine. Lug capping machine from amson engineering is a very successful machine, a very compact model with complete pneumatic working. There are two movements for capping a glass bottle with a lug cap. They are, clamping of cap with the bottle, and tightening of cap to the bottle. After a long time research and development, we have designed such a machine which can cap any sized lug caps to glass bottles. The machine is called, pneumatic lug capping machine model number aeplc80. Structure and working: this machine is having 2 pneumatic cylinders t two directions , mounted to get a free movement during capping. The cylinders are operated through a panel box mounted at one side of the unit. A pedal operating switch is provided to actuate the working. Each pressing will do each capping action. Machine is made compact and tabletop and weighs only 35 kgs. Operating this machine requires very less effort, since all the power needed is done by pneumatic cylinders. Operating is done, after bottle with cap is placed under the capping head and press the pedal operating switch. Here, the top clamping cylinder actuates, and the bottle with cap is tightly pressed to each other. Now, at the same time, another cylinder is actuated which does the capping action. The cylinder is set in such a way, that after a perfect clamp the cylinder is either slipped or stopped as per tightness required. Specifications: • machine name: pneumatically operated semi-automatic lug capping machine • machine model: aeplc80 • capping capacity: up to 80mm size cap • output: 20 cpm. • air consumption: 2 cfm, @ 5.5 bar. • number of cylinders: 2 nos. • power consumption: 230vac, 50 hz, 0.5 kwh. • machine size: 15” x 15” x 25” h. • machine weight: 35 kgs. • separate panel box provided. • table top model. • bottle and caps placed manually. • pedal switch provided for operating. • strong design requires no maintenance. • cap tightening height adjustable by hand wheel. • bottle bottom gripping surface provided. • automatic models also available on request.

Brand Name : AMSON

...more

Twin Head Vacuum Liquid Filling Machine

We, being a prime Manufacturer, Exporter & Supplier in the industry, offer Twin Head Vacuum Liquid Filling Machine. It is applied in a number of industrial purposes. The quality is ensured to be in compliance with the standards and parameters set by the industry. We make it available in a number of specifications. Its durability, high performance and dimensional accuracy make it a popular choice for varied purposes. Additional Information :We manufacture a versatile filling machine for volume filling applications. The machine is called Twin Head Vacuum filler. Very useful filling machine designed for Alcohol, perfumes, nail polish, and distillery industries. Here, the machine works on the basis of Vacuum suction from the container. Fast filling of any Glass bottles can be done by using this machine. Various volumes can be filled by adjusting the height of Bottle holder and by adjusting the vacuum filling nozzle. Machine Structure and Working : Complete machine frame is made from stainless steel frame structure, welded, and finished to mat. Total Frame structure is covered by stainless steel sheet metal of good gauge and finish .This machine is made a strong independent model. A ¼ HP 230VAC oil cooled 75LPM output capacity Vacuum pump is providing the vacuum required during filling. This unit is mounted inside the frame, so that the noise is maintained to a minimum during working. All the other parts like, liquid overflow trap, fill nozzles, are mounted over the frame structure. All material contact parts are made from stainless steel 304 quality material as per specifications. A trap vessel with suitable capacity is mounted at one side of the top to collect the overflow liquid from the bottles. Fill nozzles are 2 as per fill requirement. Various fill volumes can be filled at a time as per adjustment. Machine is easy to operate. The glass bottle to be filled is to be placed below the fill nozzle. When the handle is pressed, a gasket provided on the nozzle press on the bottle mouth and makes air tight, thus the vacuum suck air from the bottle. When the bottle is vacuum, the liquid is filled fast into it. The fill level is maintained as per the nozzle depth adjustment inside the bottle. No maintenance is required since, there is no moving parts is involved. Most economical for level filling applications. Special Features : Strong model with complete stainless steel Mat finished body All product contact parts are made of stainless steel 304 quality. High speed filling as per volume required No dripping or wastage of liquids because of vacuum and trap vessel. Multiple tilt able heads provides easiness in filling, Bottle resting platform with height adjusting facility for Nozzles. Easy to operate. Any volume can be filled from 5ml to 1 liter as per required according to nozzle depth inside the bottle. Specifications Machine size - 800 X 900 X 1500 mm H Machine weight - 90 kgs. Approx. Gross Weight including Packing - 120 kg. Number of heads - 2 Machine name - Two Head Vacuum Liquid filling Machine. Output - 15 fills per minute from each head. Power consumption - 0.5 KwH. Electricity required - 1 phase 220 VAC. 50 Hz. Vacuum pump - ¼ HP 75 LPM ( Oil cooled, MINIVAC make) All material contact parts are in SS 304 Base for bottles provided. Inbuilt vacuum pump and closed-Oil cooled type. High efficiency machine. 10 liter capacity overflow stainless steel vessel attached. Easy to operate. Low maintenance model. Fill capacity from 50ml to 1000ml or more up to 5000ml. Uses : Most suitable for filling any free flowing materials like, liquor, nail polish, syrups, perfumes, etc.

Voltage : 110V

Condition : New

Warranty : 1year

...more

Twin Head Perfume Filling Machine

Being a prominent Manufacturer, Exporter & Supplier in the industry, we present a wide range of Twin Head Perfume Filling Machine to our customers. The quality we offer is unmatched. We take special care of quality by testing the machine against the highest parameters of quality set by the industry. We provide the machine in safe packaging at affordable rates. We also deliver at your doorstep at your ease owing to our first-rate distribution system. Additional Information :Twin Head Vacuum Assisted Perfume Filling Machine we manufacture are versatile filling machine for volume filling applications mostly in Perfume Industries where the volume of filling is important. Very useful filling machine designed for perfume industries. Here, the machine works on the basis of air removal from glass or hard bottles using Vacuum suction from the bottle and liquid filling inside. Fast filling of any Glass bottles can be done by using this machine. Various volume can be filled by adjusting the height of Bottle holder and by adjusting the vacuum filling nozzle. Special Features : Strong model with complete stainless steel Mat finished covered body All product contact parts are made of stainless steel 304 quality. High speed filling as per volume required No dripping or wastage of liquids because of vacuum and trap vessel. 1 pairs of heads provides easiness in filling, Bottle resting platform with height adjusting facility for Nozzles. Easy to operate. Any volume can be filled from 2ml to 200ml as per required according to nozzle depth inside the bottle. Specifications Machine size - 600 X 500 X 1100 mm H Machine weight - 80 kgs. Approx. Gross Weight including Packing - 110 kg. Number of heads - 2 Machine name - Twin Head Vacuum filling Machine. Output - 15 fills per minute from each head @100ml. Power consumption - 0.3 KwH. Electricity required - 1 phase 220 VAC. 50 Hz. Vacuum pump - 1/4HP 75 LPM, oil cooled/Air cooled, MINIVAC make. All material contact parts are in SS 304 Base for bottles provided. High efficiency machine. 10 liter capacity overflow stainless steel vessel attached. Easy to operate. Low maintenance model. Fill capacity from 2ml to 200ml.

Voltage : 110V

Condition : New

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

Filling Range : 5ml-50ml 100ml-500ml

...more

Tube Sealing Machine Semi Automatic Lab Model

1 Piece(s) (MOQ)

We offer Tube Sealing Machine. PSCT15 is compact and strong with accurately machined metal plates and standard parts. Manufacturing and assembly is done under the observation of qualified designers and engineers to get maximum quality. Pneumatically operated model which reduces mechanical parts and there is less maintenance required. High quality parts keeping International standards. Base frame of this machine is manufactured from stainless steel square Pipe section and sheet metal, which is fabricated, welded and finished to mat. A main vertical slide unit supports total assembly, like Sealing and Trimming units. Easy rotating hand wheel helps in height adjustment for different tube heights. A cross plate is mounted carrying sealing and trimming stations at left and right sides respectively. Sealing plate is working on Linear Motion Bearings over Hardened and Ground Shafts fixed both ends by strong plates. Pneumatic cylinders are mounted and connected with the sealing plates at both sides. Sealing plates carries the textured sealing teeth where batch numbers can be inserted. Sealing width of maximum 5mm is provided with vertical line texture for sealing design. Both side batch numbers for coding is also possible on request. An in house manufactured stainless steel hot air assembly is mounted centrally over the sealing station. This assembly is insulated to avoid any danger. Trimming is done on separate station at the right side. Trimming blades are mounted on plates and pneumatic cylinder is connected at one end. Here, one blade is stationary and other blade is moving. All moving parts are covered with Stainless steel sheet metal of good gauge and finish to mat. A Bottom Horizontal slide unit is provided to move the tube holder towards Sealing and Trimming stations. There are proximity sensors provided below both stations. A Tube Holder lifter cylinder is provided at the bottom of Horizontal slide below Sealing Station. When the Tube holder is moved towards the Sealing station, the proximity sensor detects the presence of tube and holder lifter actuates to move the tube towards the Hot air tool for heating the inside wall of tube perfectly. Additional Features: 1. Any tube diameter from 16 mm to 50 mm can be sealed and trimmed in this model. 2. Tube diameter changes but holder outside diameter same. This helps in holding any sized tubes in location without changing centre. 3. Easy adjustment of sealing station height according to different tube heights by rotation hand wheels. 4. Any tube heights from 60 mm to 250mm can be sealed and trimmed. 5. 1 pair of different tube holders supplied with the machine. 6. All types of tubes can be sealed whether it is plastic or Laminated LDMonolayerMulti Layer etc which have plastic inner lining. 7. Adjustable digital temperature controller to select different temperatures for different materials of tubes. 8. In-House Manufactured Stainless steel Hot Air Gun with high efficiency. 9. Adjustable heating time and sealing time for different tubes. 10. Solenoid operated trimming and sealing station and can be operated by push button in manual mode. 11. Separate air pressure regulator for the machine to maintain air pressure steady. 12. Flow control valve to maintain hot air flow to the tube ends. 13. Compact model in its class requires small area to occupy. 14. Very economical for beginners and R&D purposes. 15. 2 complete set of batch codes- Numerical letter- 0-9 supplied with the machine. 16. Hard chrome plated Sealing teeth with batch code inserting facility. Technical Specifications: • Overall size: 500mmL X 500mmW X 1200mm H • Packing size: 2Ft Length X 2 Ft Width X 4 Ft Height. • Total machine Weight: Approx: 75Kgs. • Gross weight including packing: 110 Kgs. • Power supply required: 220VAC,50HZ,2KW • Heater power: 2500Watts • Air pressure required: 5.5 Kgcm2 ( 4 cfm- 2 HP Air Compressor) • Complete Stainless Steel Hot air assembly. • Sealing type: Hot air assisted Pneumatically operated sealing jaws. • Output: 15 tubesminute. • Tube sizes: Diameter16 mm to 50 mm • Tube length: 60mm to 250mm. • Tube placing: Manual. • Machine model: PSCT15 • Number of Batch codes inserted: 10 Nos. • Both Side Batch coding possible on request. • Batch code size: 2mm W X 4mm H X 12.55mm Length • Sealing width: 5-6mm • Machine type: Semi-automatic tube sealing, coding, and trimming machine, Standard MODEL with all Contact Parts in SS304 Quality Machined, fabricated and finished to Mat, and all other non-contact parts are made in carbon steel finished and chrome plated quality.. • Air Pressure required: 5.5 kgcm2 @ 4 cfm (80 psi)(2Hp Twin Cylinder SingleThree Phase) • All moving parts, machine frame covered by SS sheet metal of good gauge and finish. • Panel box inbuilt carrying timers, Temperature controllers and operating switches.

Brand Name : AMSON

...more

Tube Sealing Machine Semi Automatic

1 Set(s) (MOQ)

Psct15 model is a compact machine with single tube seal facility at a time. But it is very much useful for low and medium production industries. Psct15 is small but strong with accurately machined metal plates and standard parts. Manufacturing and assembly is done perfectly under the instruction of qualified designers and engineers to get maximum quality. Pneumatically operated model which reduces mechanical parts and there is less maintenance required. High quality parts keeping international standards. Base frame of this machine is manufactured from stainless steel pipe section and sheet metal, which is fabricated, welded and finished. A main vertical slide unit supports total assembly, like sealing and trimming units. Easy rotating hand wheel helps in height adjustment for different tube heights. a cross plate is mounted carrying sealing and trimming stations at left and right sides respectively. sealing plate is working on linear motion bearings over hardened and ground shafts fixed both ends by strong plates. Pneumatic cylinders are mounted and connected with the sealing plates at both sides. Sealing plates carries the batch numbers. Sealing width of maximum 6mm is provided with vertical line texture for sealing design. A hot air assembly is mounted centrally over the sealing station. Stainless steel made parts are used for hot air tool making. This assembly is fixed over the sealing station with insulation. trimming is done on separate station. Trimming blades are mounted on holders and pneumatic cylinder is connected at one end. Here, one blade is stationary and other blade is moving. All moving parts are covered with stainless steel sheet metal of good gauge and finish to mat. a bottom horizontal slide unit is provided to move the tube holder towards sealing and trimming stations. A tube holder lifter cylinder is provided at the bottom of sealing station. When the tube holder is moved towards the sealing station, the holder lifter actuates and moves the tube end towards the hot air tool for heating the inside wall of tube perfectly. working of psct15 model each filled tube is placed manually in the tube holder placed on horizontal slide unit when start sealing operation. When the slide unit is moved towards the sealing area, a proximity switch is activated and gives pulse to the machine, this inturn actuate the lifting cylinder, the hot air tool comes in contact with tube, and heats the sealing area of tube. Hot air is passed for a pre-set time only to the area where to seal. This avoids unwanted heating of filled material inside the tube. Now the lifter moves down away from hot air gun and at the same time, both sealing jaws operate and seal the tube end. Perfect sealing of tube end with desired sealing texture and batch coding is done. Since inside of the tube is heated, no harm for outside of the tube is a result. additional features: 1. any tube diameter from 10 mm to 50 mm can be sealed and trimmed in this model. 2. tube diameter changes but holder outside diameter same. This helps in holding any sized tubes in location without changing centre. 3. easy adjustment of sealing station height according to different tube heights by rotation hand wheels. 4. any tube heights from 80 mm to 250mm can be sealed and trimmed. 5. 1 pair of different tube holders supplied with the machine. 6. all types of tubes can be sealed whether it is plastic or laminated. 7. adjustable digital temperature controller to select different temperatures for different materials of tubes. 8. adjustable heating time and sealing time for different tubes. 9. solenoid operated trimming and batch coding station and can be operated by push button. 10. separate air pressure regulator for the machine to maintain air pressure steady. 11. flow control valve to maintain hot air flow to the tube ends. 12. compact and economy model requires small area to occupy. 13. 1 complete set of batch codes- numerical letter- 0-9 supplied with the machine. 14. hard chrome plated sealing teeth with specially designed batch code holder. Technical specifications: • overall size: 500mml x 500mmw x 1200mm h • packing size: 2ft length x 2 ft width x 4 ft height. • total weight: approx: 75kgs. • gross weight including packing: 125 kgs. • power supply required: 220vac,50hz,2kw • heater power: 1500watts • air pressure required: 5.5 kgcm2 ( 10 cfm) • complete stainless steel hot air assembly. • sealing type: hot air assisted pneumatically operated sealing jaws. • output: 12 -15 tubesminute. • tube sizes: diameter10 mm to 50 mm • tube length: 80mm to 250mm. • tube placing: manual. • machine model: psct15 • number of batch codes inserted: 10 nos. • both side batch coding possible on request. • batch code size: 2mm w x 4mm h x 12.55mm length • machine type: semi-automatic tube sealing, coding, and trimming machine, standard model with all contact parts in ss304 quality machined, fabricated and finished to mat, and all other non-contact parts are made in carbon steel finished and chrome plated quality. • air pressure required: 5.5 kgcm2 @ 10 cfm(1hp twin cylinder singlethree phase) • all moving parts, machine frame covered by ss sheet metal of good gauge and finish. • panel box inbuilt carrying timers, temperature controllers and operating switches.

...more

Tube Sealing Machine

1 Piece(s) (MOQ)

We offer tube sealing machine. Psct15 is compact and strong with accurately machined metal plates and standard parts. Manufacturing and assembly is done under the observation of qualified designers and engineers to get maximum quality. Pneumatically operated model which reduces mechanical parts and there is less maintenance required. High quality parts keeping international standards. Base frame of this machine is manufactured from stainless steel square pipe section and sheet metal, which is fabricated, welded and finished to mat. A main vertical slide unit supports total assembly, like sealing and trimming units. Easy rotating hand wheel helps in height adjustment for different tube heights. a cross plate is mounted carrying sealing and trimming stations at left and right sides respectively. Sealing plate is working on linear motion bearings over hardened and ground shafts fixed both ends by strong plates. Pneumatic cylinders are mounted and connected with the sealing plates at both sides. Sealing plates carries the textured sealing teeth where batch numbers can be inserted. Sealing width of maximum 5mm is provided with vertical line texture for sealing design. Both side batch numbers for coding is also possible on request. An in house manufactured stainless steel hot air assembly is mounted centrally over the sealing station. This assembly is insulated to avoid any danger. Trimming is done on separate station at the right side. Trimming blades are mounted on plates and pneumatic cylinder is connected at one end. Here, one blade is stationary and other blade is moving. All moving parts are covered with stainless steel sheet metal of good gauge and finish to mat. A bottom horizontal slide unit is provided to move the tube holder towards sealing and trimming stations. There are proximity sensors provided below both stations. a tube holder lifter cylinder is provided at the bottom of horizontal slide below sealing station. When the tube holder is moved towards the sealing station, the proximity sensor detects the presence of tube and holder lifter actuates to move the tube towards the hot air tool for heating the inside wall of tube perfectly. • overall size: 500mml x 500mmw x 1200mm h • packing size: 2ft length x 2 ft width x 4 ft height. • total machine weight: approx: 75kgs. • gross weight including packing: 110 kgs. • power supply required: 220vac,50hz,2kw • heater power: 2500watts • air pressure required: 5.5 kgcm2 ( 4 cfm- 2 hp air compressor) • complete stainless steel hot air assembly. • sealing type: hot air assisted pneumatically operated sealing jaws. • output: 15 tubesminute. • tube sizes: diameter16 mm to 50 mm • tube length: 60mm to 250mm. • tube placing: manual. • machine model: psct15 • number of batch codes inserted: 10 nos. • both side batch coding possible on request. • batch code size: 2mm w x 4mm h x 12.55mm length • sealing width: 5-6mm • machine type: semi-automatic tube sealing, coding, and trimming machine, standard model with all contact parts in ss304 quality machined, fabricated and finished to mat, and all other non-contact parts are made in carbon steel finished and chrome plated quality. • air pressure required: 5.5 kgcm2 @ 4 cfm (80 psi)(2hp twin cylinder singlethree phase) • all moving parts, machine frame covered by ss sheet metal of good gauge and finish. • panel box inbuilt carrying timers, temperature controllers and operating switches.

Brand Name : AMSON

...more

Tube Sealing Coding Trimming Machine

1 Piece(s) (MOQ)

We offer tube sealing coding trimming machine semi-automatic. Psct15 is compact and strong with accurately machined metal plates and standard parts. Manufacturing and assembly is done under the observation of qualified designers and engineers to get maximum quality. Pneumatically operated model which reduces mechanical parts and there is less maintenance required. High quality parts keeping international standards. Base frame of this machine is manufactured from stainless steel square pipe section and sheet metal, which is fabricated, welded and finished to mat. A main vertical slide unit supports total assembly, like sealing and trimming units. Easy rotating hand wheel helps in height adjustment for different tube heights. a cross plate is mounted carrying sealing and trimming stations at left and right sides respectively. Sealing plate is working on linear motion bearings over hardened and ground shafts fixed both ends by strong plates. Pneumatic cylinders are mounted and connected with the sealing plates at both sides. Sealing plates carries the textured sealing teeth where batch numbers can be inserted. Sealing width of maximum 5mm is provided with vertical line texture for sealing design. Both side batch numbers for coding is also possible on request. An in house manufactured stainless steel hot air assembly is mounted centrally over the sealing station. This assembly is insulated to avoid any danger. Trimming is done on separate station at the right side. Trimming blades are mounted on plates and pneumatic cylinder is connected at one end. Here, one blade is stationary and other blade is moving. All moving parts are covered with stainless steel sheet metal of good gauge and finish to mat. A bottom horizontal slide unit is provided to move the tube holder towards sealing and trimming stations. There are proximity sensors provided below both stations. a tube holder lifter cylinder is provided at the bottom of horizontal slide below sealing station. When the tube holder is moved towards the sealing station, the proximity sensor detects the presence of tube and holder lifter actuates to move the tube towards the hot air tool for heating the inside wall of tube perfectly. Technical specifications: • overall size: 500mml x 500mmw x 1200mm h • packing size: 2ft length x 2 ft width x 4 ft height. • total machine weight: approx: 75kgs. • gross weight including packing: 110 kgs. • power supply required: 220vac,50hz,2kw • heater power: 2500watts • air pressure required: 5.5 kgcm2 ( 4 cfm- 2 hp air compressor) • complete stainless steel hot air assembly. • sealing type: hot air assisted pneumatically operated sealing jaws. • output: 15 tubesminute. • tube sizes: diameter16 mm to 50 mm • tube length: 60mm to 250mm. • tube placing: manual. • machine model: psct15 • number of batch codes inserted: 10 nos. • both side batch coding possible on request. • batch code size: 2mm w x 4mm h x 12.55mm length • sealing width: 5-6mm • machine type: semi-automatic tube sealing, coding, and trimming machine, standard model with all contact parts in ss304 quality machined, fabricated and finished to mat, and all other non-contact parts are made in carbon steel finished and chrome plated quality. • air pressure required: 5.5 kgcm2 @ 4 cfm (80 psi)(2hp twin cylinder singlethree phase) • all moving parts, machine frame covered by ss sheet metal of good gauge and finish. • panel box inbuilt carrying timers, temperature controllers and operating switches

Brand Name : AMSON ENGINEERING

...more

tube filling sealing machines

1 Piece(s) (MOQ)

Single head eight station turret type rotary lami or plastic tube filling sealing and coding machine manufactured by amson engineering model no. Aets01100, which can fill and seal tubes up to 100gms. Output can be up to 40 tubes per minute maximum. This machine can perform operations like, tube filling, hot air assisted heating of tube ends, pneumatic assisted sealing, batch coding, trimming of unwanted sealed end, and automatic ejection of finished tubes. Tube placing is manual and all other operations are automatic. this machine is compact and comes with parts like, heavy duty frame structure manufactured with stainless steel pipe sections fabricated and top plate stainless steel cladded, complete machine frame is covered by stainless steel sheet metal mat finished, rotary 8 station aluminium turret, 12 hp 3 phase induction motor and worm gearbox, grooved cam indexer, drive attached with control, 22 liter capacity ss hopper- 16 gauge, ss filling piston barrel for materials such as fairness creams, pain balms, toothpaste, shampoo, cream, gel, etc., with a maximum fill capacity from 20gms up to 200 gms. Automatic filling of tubes done when present at filling station with a “no tube no fill” proximity sensor. Hot air assisted sealing. Height adjustable stations, pneumatically operated sealing jaws with vertical line texture, and trimming of sealed ends to get a finished end, batch coding facility on both sides of tube with hard punches which can be easily set by any labour, stainless steel material contact parts of filling, no tube no filling process proximity switch, 0-9 hard batch coding punches 2 sets(20 nos. Total) ,automatic ejection of filled tubes by pneumatic ejector pin, 12 hp ac 3 phase motor and motor with variable frequency speed control to adjust the output speeds,

...more

Manual Tube Filling Machine

1 Piece(s) (MOQ)

We are offering manual tube filling machine. Manual hand operated paste filling machine model aehpf series can also called by many names such as tube filling machine, cream filling machine, curd filling machine, mehandi filling machine, chuna filling machine, fevicol filling machine, adhesive filling machine, gel filling machine etc, since almost all types of semi liquids pasty materials can be filled by using this machine. A very well known machine in all packaging industry. This machine is proven and manufactured for decades, since this is the basic paste filling machine which has the ability to fill any semi liquids accurately. Compact and easy operating and low maintenance makes this machine the winner among all the filling machines. Brief about the product: this is the basic and proved machine for paste or tube filling industry. Very widely used and famous among small and medium production industry. Hand operated paste filling machine is very economical, easy to operate and easy to maintain type. Any semi-liquids and pasty materials, like cream, pastes, gel, ketchup, and other same kind materials can be easily filled accurately by using this machine. Table top model which requires less space to fit and start the production. Inbuilt hopper and operating handle completes this machine for taking production. Machine structure and working: machine base and main structure is made from cast steel which is machined and duly powder coated to get the finish. There are parts like hopper and operating lever, fill barrel, nozzle, and adjustment screw are present in all machines. There is a strong hopper provided with required volume capacity as per material. Small models comes with moving hopper and bigger models comes with steady hopper. The hopper is made from stainless steel 304 as per specification. Fill barrel is another main part in this machine. This is also made from stainless steel. The inside of each barrel is ground to get mirror finish. barrel design is done as per fill volume requirements. The barrels are available in 15gms, 25gms, 50gms, 100gms, 150gms, 250gms, and also 500gms. The piston is a specially designed one, which does suction and filling in one stroke. fill nozzles are welded to the barrel. The mouth of nozzle is maintained towards down to fill smoothly into containers or tubes below the fill barrel. Specifications; • machine model: aehpf50 • machine type: hand operated paste filling machine • machine dimensions: 8” w x 10” b x 24” l • machine weight: 20 kgs. • packing size: 10” x 12” x 25”h • gross weight: 35 kgs. • packing: wooden box. • fill range: 5gms- 50gms as per barrel capacity • fill capacity: up to 20 fills per minute as per operator skill. • hopper capacity: 15 liters. • all material contact parts are made in stainless steel 304 316 as per specifications. • bigger models available on request up to 500gms. • steady hopper for bigger models. • motorised machines also available on request. uses: most suitable for mehandi, cream, curd, fevicol, pastes, adhesives, gels, and any other herbal, chemical, cosmetic pastes.

Brand Name : AMSON

...more

Table Top Powder Dosing Machine

Being a well known Manufacturer, Exporter & Supplier, we are dedicated towards providing the best quality of Table Top Powder Dosing Machine. As a quality-oriented organization, we are focused to provide our customers excellent quality. Our product is widely appreciated for its optimum performance, durability and high effectiveness. Customers can avail it from us in attractive and protective packages at affordable rate. For our customers, we make available the option of home delivery. Additional Information : Table top Model Powder filler is made strong and vibration free by its specially designed Pillar structure. This is made from Mild steel ROUND Pipe section of good thickness Hard chrome Plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the Augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a Bearing housing holds and rotates freely when the machine is operated. The driven shaft is holding an accurately machined stainless steel AUGUR which performs the filling inside the Nozzle. The lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The start/stop signals to the auger drive control the pre-set weight in Weigh metric fillers. Technical Specifications Afaew 30 Machine size - 600 L X 600W X 1000mm height. Machine Model - AFAEW30- Weigh Based Drive Motor - 1/2 HP 230/415 VAC 50Hz, 1440 rpm. with VFD(Variable Frequency Drive) Power - 230VAC 50Hz Single Phase 0.5 KwH Electromagnetic Clutch- Brake - HSCBC 100, 24 VAC Cryotron Make Load Cell Capacity - 1 Kg, 500Mg. All material contact parts in S.S. 304 Stainless steel 304 Augur (Screw) type filling. Hopper size 15 Liters (S.S 304), 16 Gauge, mirror finish for AFAEW30 Fill capacity - 1gm-30 gms at a time as per preset weight on digital weigh machine Additional Features : Augur Based filling equipped with digital weighing unit. One touch Start by a foot-switch Drive through electro-magnetic clutch brake system to get high accuracy filling. High output and increased efficiency. Output of 15 fills/minute can be achieved. High Accuracy up-to +/- 0.5% of fill volume. Low maintenance needed in this model

Type : Dosing Pumps

Application : Water Supply

Weight : 10-20kg

Color : Silver

Voltage : 110V

Automatic Grade : Semi Automatic

Power : 1-3kw

Driven Type : Electronic

...more

Table Top Liquid Filling Machine

1 Piece(s) (MOQ)

We are offering table top liquid filling machine. This machine manufactured by amson engineering, mumbai, is the basic model for any liquid filling machines used in any industries. name of this machine is volumetric liquid filling machine, also known as hand operated liquid filler. Model is aevhf series. This machine is unique among small scale production units, because it is the most economical and of course it is easy in operation. High fill abilities and various settable fill volumes as per requirement makes this the perfect filling machine. Any free flowing material or even partially free flowing material which is to be filled by volume can correctly filled by this machine. Accuracy is high in this machine. Machine structure and working: machine consists of a small bracket structure, made of mild steel pipe structure. A vertically hanging syringe with a non-return valve mechanism is the filling unit. there is an operating lever provided at front side. A set screw is given at the bottom of the moving connector lever by which we can adjust stroke and there by the fill volume. Machine body is duly powder coated and finished. Gmp model machines are made with stainless steel for bracket. special features: aehvf model machine is small, compact and light weight. Total weight including syringe is only 20 kgs. So, the packing size is also less. There are many syringes you can select as per your requirement. The syringes are for filling volumes like 10-25ml, 25-50ml, 50-110ml,10ml-150ml, 100ml-260ml, 250ml-500ml etc. Machine comes in standard polymer powder coated or gmp models available as per order. specifications; • machine model: aehvf100 • machine type: hand operated volumetric liquid filling machine • machine dimensions: 8” w x 12” b x 23” h • machine weight: 20 kgs. • packing size: 10” x 15” x 22”h • gross weight: 30 kgs. • packing: wooden box. • fill range: 5ml- 100 ml syringe capacity. • fill capacity: up to 15 fills per minute maximum, • various fill volume setting possible by set screw provided. • nozzle height adjustable as per required. • all material contact parts are made in ss304316 quality as per specifications. • silicon rubber pipes at suction and delivery sides for hot liquids. • no separate hopper provided with this machine. Liquid can be sucked from any vessel placed below the machine level. uses: best useful for perfumes, syrups, lotions, any liquids, pesticides, oils, hot liquids, and shampoo etc. complete manual operating. No electricity required in this machine

Brand Name : AMSON

...more

Syrup Filling Machine

1 Piece(s) (MOQ)

We are offering Syrup Filling Machine. This semi automatic volumetric liquid filling machine, model no: aevmf021000 can be single or two head, table top, complete gmp semi-gmp model used to fill variety of liquids. Semi automatic volumetric liquid filling machine can be used for filling different types of glass. Plastic, metal containers. Any free flowing or partially free flowing liquids with comparatively low viscosity with volume filling requirement can easily and accurately filled with this machine. Output of this machine is very high as compared to manual hand operated machines. The main speciality of this machine is there is no human power is required to fill the bottle. The only job is to start the machine, and to place the empty bottles below the filling nozzle. All the other jobs like suction volume measuring and filling are done by this machine itself. Twin head machines in this series can fill two equal or different volumes at a time. If two peoples are doing the filling, then the output can be higher upto 16 fills per minute as per syringe size. Machine structure and working: the aevmf021000 works on volumetric principle and is fitted with singletwo syringes on both the sides. The motor and gear box are covered in a stainless steel cabinet. The desired volume can be adjusted by increasing or decreasing the eccentricity of the cam provided with the machine. Bottles are kept bellow the nozzles manually. there is stainless steel syringes and piston at both sides which do the filling. A non-return valve helps the control of flow towards and from the syringe during working. A polished ss nozzle is provided for both the syringes connected by pipes and mounted on height adjustable supports. The human labor is required to operate this machine is only one person. When main switch is on, the machine starts the filling. Each filling is done at a particular interval. The bottle to be filled is to be placed under the fill nozzle and after each filling, removed by hands. output 16 bottles per minute from each head depending on type liquid and fill volume. All the contact parts are made of ss 304 as per material to be filled as per specification. special features: machine is made compact with sturdy internal frame structure. Complete machine frame is covered with stainless steel 304 quality sheet metal of good gauge and finished to mirror. All working parts like, motor, gear box, and shafts are inside the cover to avoid any danger. Adjustable fill volume by an eccentric cam screw rotation. Flame proof motor and switches provided for inflammable material filling on request. Very useful for soft drinks, chemicals, pesticides, oils, syrups, lotions etc. Specifications for double head liquid filler: • machine size: 400mm l x 400mm w x 500mm h • weight: 55kgs approx. • syringe capacity: 50ml-1000ml max(ss syringe) at one side • syringe capacity: 50ml- 1000ml max(ss syringe) at other side • machine model: aevmf021000 • settable fill volume by cam and screw. • motor capacity: 1hp 1440rpm, 220vac, 50hz, • gear box: 60:1 ratio. • output: 8 fills per syringe at each side(16 fills per minute total from both heads) • number of fill nozzles: 2 nos. • fill nozzles and output pipe provided, • no separate hopper provided, input of (suction) liquid can be done from any vessel. • heating jacketed vessel of any capacity can be available as per order as optional. • 1 single person can operate the machine. • change part syringe (compatible) available on order at extra cost, for different volume filling.

Brand Name : AMSON

...more

Single Head Automatic Linear Piston Filling Machine

We are engaged in delivering Single Head Automatic Linear Piston Filling Machine being an esteemed figure in the industry. As a Manufacturer, Exporter & Supplier, we cater to the specific requirement of customers in different quality. Quality control team, hired by us, is committed to raising the quality up to the industrial quality standards. Our offered range is recognized for durability, high performance and sturdiness. This quality is available for our valued customers at affordable rates. Additional Information :Automatic Conveyor type Single Head Piston Filling Machine Model AEAPPF1000 is an universal filling machine. With this machine, you can fill paste material very accurately and fast into any containers. A very user-friendly model with low maintenance requirement. This machine is equipped with pneumatically operated filling mechanism and a motorized conveying unit. The whole unit is strong and used are heavy duty parts. Less rotating parts means low maintenance. Accuracy of filling is maximum up to 0.5% of the volume. Various volume capacities from 50 gm to 1000gms can easily filled with this machine. Bigger volumes also available on request.Special Features : Complete GMP Model suitable for Pharmaceutical Applications and food industries. Clean filling without dripping, Tri-clover (sanitary) fittings attached so that easy product change over after cleaning possible within minutes. Any material from free flowing liquids to hard pastes can be filled by same machine. High accuracy in each filling. Filling volume can be adjusted without stopping the machine with hand wheel. No dripping so no wastage of product and so clean filling assured. Container stopping facility attached for filling, so the conveyor is moving all the time to reduce the time lag. Operating Panel Box with all electrical control switches, timer mounted away from fill area. Specifications for Conveyor Type Automatic Pneumatic Piston Filler Machine Model - Automatic Paste Filler Pneumatic, AEAPPF1000 Machine overall size; 8 ft L X 3Ft W X 6.5 Ft H Machine weight - 285 kgs approx. Gross weight - 400 Kgs. All Material contact Parts are in SS304 grade, finished to mat. Fill Barrel size - 80mm Bore X 200 Length(For 1000gms filling) Output - 20 fills per minute with bigger nozzle. Fill Capacity - 100gms-1000gms as per barrel size and settable volume by hand wheel. Compressor required - 5.5 Kg.cm2, 4 cfm.(2 HP twin cylinder, 3/1 phase) to be arranged by you. Inbuilt Panel Box with timers switches and valves. 60 Liter Hopper comes with this machine; Also Material can be sucked from any overhead vessel. Adjustable stroke and fill volume with a hand wheel provided with the machine.

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

Warranty : 5years

...more

Semi Automatic Volumetric Liquid Filling Machine

Riding on our experience in the industry, we, as a Manufacturer, Exporter & Supplier of Semi Automatic Volumetric Liquid Filling Machine have positioned us in the upper echelons of the industry. Our distribution network allows us to facilitate quick and convenient delivery in a matter of time at your doorstep. Its dimensional accuracy and sturdiness makes it an interesting proposition. We offer the supreme quality at economical rates. Additional Information : This semi automatic volumetric liquid filling machine, Model No: AEVMF021000 is two head, table mount type, semi-GMP model used to fill variety of liquids/oils. Semi automatic volumetric liquid filling machine can be used for filling different types of glass, Plastic, Metal containers. Any free flowing or partially free flowing liquids with comparatively low viscosity with volume filling requirement can easily and accurately filled with this machine. Output of this machine is very high as compared to Manual Hand operated machines. The main speciality of this machine is there is no human power is required to fill the bottle. The only job is to start the machine, and to place the empty bottles below the filling nozzle. All the other jobs like suction volume measuring and filling are done by this machine itself. Twin head machines in this series can fill two equal or different volumes at a time. If two peoples are doing the filling, then the output can be higher up to 8 fills per minute as per syringe size. Machine Structure and Working : The AEVMF021000 works on volumetric principle and is fitted with single/two syringes on both the sides. The motor and gear box are covered in a Stainless steel cabinet. The desired volume can be adjusted by increasing or decreasing the eccentricity of the cam provided with the machine. Bottles are kept bellow the nozzles manually. There is Stainless steel Syringes and Piston at both sides which do the filling. A non-return valve helps the control of flow towards and from the syringe during working. A Polished SS Nozzle is provided for both the syringes connected by pipes and mounted on height adjustable supports. The human labour is required to operate this machine is only one. The main switch is to be started to start the filling. Each filling is done at particular intervals. The bottles to be filled are to be placed under the fill nozzle after each filling after removing the filled bottles. Output 8 bottles per minute from each head depending on type liquid and fill volume. All the product contact parts are made of SS 304 as per material to be filled/ as per specification. Special Features : Machine is made compact with sturdy internal frame structure. Complete machine frame is covered with stainless steel 304 quality sheet metal of good gauge and finished to mirror. All working parts like, motor, gear box, and shafts are inside the cover to avoid any danger. Adjustable fill volume by an eccentric cam screw rotation. Very useful for pesticides, oils, syrups, lotions etc. Specifications for Double Head Liquid Filler Machine size - 800mm L X 900mm W X 1000mm H Weight - 125kgs approx. Syringe capacity - 100ml-1000ml max(SS Syringe) at one side Syringe capacity - 100ml - 1000ml max(SS Syringe) at other side Machine Model - AEVMF021000 Settable fill volume by cam and screw. Motor capacity - 1HP 1440Rpm, 220VAC, 50Hz, Gear Box - 60 - 1 ratio. Output - 4 fills per syringe at each side(8 fills per minute total from both heads) Number of fill nozzles - 2 nos. Fill nozzles and output pipe provided, No separate Hopper provided, Input of (Suction) liquid can be done from any vessel. Heating Jacketed Vessel of any capacity can be available as per order as optional. 1 single person can operate the machine. Change part Syringe (Compatible)available on order at extra cost, for different volume filling.

Condition : New

Power : 15Kw

...more

semi automatic tube sealing machines

1 Piece(s) (MOQ)

Psct15 is compact and sturdy machine for sealing and trimming laminated filled tubes in medium output. A high efficient and simple to operate design from amson engineering, by which you can seal, stamp batch code and trim around up to 3000 sealed tubes in 8 hour shift. Psct15 is suitable for cosmetic and pharma industries where the daily production is medium. This model can be also used for lab and r&d purpose because each time a single tube is sealed or trimmed. The machine occupies a small area of floor space (2 ft x 2 ft). Peculiarity of this design is all operations are done pneumatically. There are switches for auto and manual selection. Each operation can be individually selected by electrical push buttons. Inbuilt panel box at the front side, having main operating switches and controls like mains on-off, emergency stop, digital temperature control are given. Timers for heating, sealing, trimming are mounted at the front operating panel. A set of solenoid valves responsible for the synchronized operation of the machine is safely fitted at separate chamber on the back bottom side of the machine.

...more

Semi Automatic Tube Sealing Machine

We, as a Manufacturer, Exporter & Supplier, are involved in offering Semi Automatic Tube Sealing Machine. The machine on offer is durable and robust. Our team of well trained staff keeps manufacturing process under stringent supervision to ensure our quality is in conformity with different standards set by industry. Hence, our customers can rest assured of the quality. We offer a range of designs and specifications. Additional Information : PSCT15 is compact and sturdy machine for sealing, Batch coding and trimming Plastic seamless or Laminated plastic tubes which are already filled. A high efficient and simple to operate design from AMSON Engineering, by which you can seal, stamp Batch Code and trim around 3000 sealed tubes in 8 hour shift. PSCT15 is suitable for Cosmetic and Pharma industries where the daily production is medium. This model can be also used for lab and R&D purpose because each time a single tube is sealed or trimmed. The Machine occupies a small area of floor space ( 2 ft X 2 ft). Peculiarity of this design is all operations are done pneumatically. There are switches for semi-Auto and Manual selection. Each operation can be individually selected by electrical Push buttons. Inbuilt Panel box at the front side, having Main operating switches and controls like Mains ON-OFF, Digital Temperature control are given. Timers for Heating, Sealing, Trimming are fitted at the front operating side to select the time and temperature easily according to the tube characteristics. A separate chamber at the back bottom side of the Machine hold the pneumatic controls. Additional Features : Any tube diameter from 16 mm to 50 mm can be sealed and trimmed in this model. Tube diameter changes but holder outside diameter same. This helps in holding any sized tubes in location without changing centre. Easy adjustment of sealing station height according to different tube heights by rotation hand wheels. Any tube heights from 60 mm to 230mm can be sealed and trimmed. 1 pair of different tube holders supplied with the machine. All types of tubes can be sealed whether it is plastic or Laminated/ LD/Monolayer/Multi Layer etc which have plastic inner lining. Adjustable digital temperature controller to select different temperatures for different materials of tubes. In-House Manufactured Stainless steel Hot Air Gun with high efficiency. Adjustable heating time and sealing time for different tubes. Solenoid operated trimming and batch coding station and can be operated by push button. Separate air pressure regulator for the machine to maintain air pressure steady. Flow control valve to maintain hot air flow to the tube ends. Compact and economy model requires small area to occupy. 2 complete sets of batch codes- Numerical letter- 0-9 supplied with the machine. Hard chrome plated Sealing teeth with specially designed batch code holder. Technical Specifications Overall size - 550mmL X 550mmW X 1400mm H Packing size - 2Ft Length X 2 Ft Width X 5 Ft Height. Total Weight - Approx - 85Kgs. Gross weight including packing - 120 Kgs. Power supply required - 220VAC,50HZ,4.5KW Heater power - 3500Watts(3.5Kw) Electricity Required - 4.5KwH, 220VAC, Single Phase, 50 Hz, Or as per customer requirement. Air pressure required - 5.5 Kg/cm2 ( 4 cfm- 2 HP Air Compressor) Complete Stainless Steel Hot air assembly. Sealing type - Hot air assisted Pneumatically operated sealing jaws. Output - 10 tubes/minute. Tube sizes - Diameter16 mm to 50 mm Tube length - 60mm to 230mm. Sealing - Vertical texture, 5-7mm width possible. Tube placing - Manual. Machine model - PSCT15 Number of Batch codes inserted in sealing teeth - 10 Nos. or as per required. Both Side Batch coding possible on request. Batch code size - 2mm W X 4mm H X 12.55mm Length Machine type - Semi-automatic tube sealing, coding, and trimming machine, Standard MODEL with stainless steel frame fabricated and finished to Mat, and all other non-contact parts are made in carbon steel finished and chrome plated quality.. Air Pressure required - 5.5 kg/cm2 @ 4 cfm(2Hp Twin Cylinder Single/Three Phase) All moving parts, machine frame covered by SS sheet metal of good gauge and finish. Panel box inbuilt carrying timers, Temperature controllers and operating switches.

Voltage : 110V

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

...more

Semi Automatic Tube Filling & Sealing Machine

Holding years of expertise in the industry, we, as a Manufacturer, Exporter & Supplier, offer Semi Automatic Tube Filling & Sealing Machine. We manufacture the best quality thanks to our skilled professionals, sophisticated technology and latest machines. It is suitable for different applications across various industries. The raw material used in manufacturing process is procured from reliable vendors who refuse to compromise with quality. The supreme quality makes the machine popular among customers. Additional Information :d simple to operate design from AMSON Engineering, by which you can fill, seal, stamp Batch Code and trim around 3000 sealed tubes in 8 hour shift. AEPFSCT15 is suitable for Cosmetic and Pharma industries where the daily production is medium. This model can be also used for lab and R&D purpose because each time a single tube is sealed or trimmed. The Machine occupies a small area of floor space ( 2 ft X 2 ft). Peculiarity of this design is all operations are done pneumatically. There are switches for semi-Auto and Manual selection. Each operation can be individually selected by electrical Push buttons. Inbuilt Panel box at the front side, having Main operating switches and controls like Mains ON-OFF, Digital timers, Digital Temperature control are given. All Timers for Filling, Heating, Sealing, Trimming are fitted at the front operating side to select the time and temperature easily according to the tube characteristics. A separate chamber at the back bottom side of the Machine hold the pneumatic controls such as electrically operated solenoid valves and manifolds flow control valves etc.Additional Features : Any tube diameter from 16 mm to 50 mm can be Filled , sealed and trimmed in this model. Tube diameter changes but holder outside diameter same. This helps in holding any sized tubes in location without changing centre. Easy adjustment of Filling sealing station height according to different tube heights by rotation hand wheels. Any tube heights from 60 mm to 230mm can be sealed and trimmed. 1 pair of different tube holders supplied with the machine. All types of tubes can be sealed whether it is plastic or Laminated/ LD/Monolayer/Multi Layer etc which have plastic inner lining. Adjustable digital temperature controller to select different temperatures for different materials of tubes. In-House Manufactured Stainless steel Hot Air Gun with high efficiency. Adjustable heating time and sealing time for different tubes. Solenoid operated trimming and batch coding station and can be operated by push button. Separate air pressure regulator for the machine to maintain air pressure steady. Flow control valve to maintain hot air flow to the tube ends. Compact and economy model requires small area to occupy. 2 complete sets of batch codes- Numerical letter- 0-9 supplied with the machine. Hard chrome plated Sealing teeth with specially designed batch code holder. Product hopper stainless steel 304 quality standard size of 10 liters provided. Technical Specifications : Overall size: 550mmL X 550mmW X 1500mm H Packing size: 2Ft Length X 2 Ft Width X 5 Ft Height. Total Weight: Approx: 115Kgs. Gross weight including packing: 150 Kgs. Power supply required: 220VAC,50HZ,4.5KW Heater power: 3500Watts(3.5Kw) Electricity Required: 4.5KwH, 220VAC, Single Phase, 50 Hz, Or as per customer requirement. Air pressure required: 5.5 Kg/cm2 ( 4 cfm- 2 HP Air Compressor) Complete Stainless Steel Hot air assembly. Sealing type: Hot air assisted Pneumatically operated sealing jaws. Output: 10 tubes/minute. Tube sizes: Diameter16 mm to 50 mm Tube length: 60mm to 230mm. Sealing: Vertical texture, 5-7mm width possible. Tube placing: Manual. Machine model: AEPFSCT15 Number of Batch codes inserted in sealing teeth: 10 Nos. or as per required. Both Side Batch coding possible on request. Batch code size: 2mm W X 4mm H X 12.55mm Length Machine type: Semi-automatic tube Filling sealing, coding, and trimming machine, Standard MODEL with stainless steel frame fabricated and finished to Mat, and all other non-contact parts are made in carbon steel finished and chrome plated quality.. Air Pressure required: 5.5 kg/cm2 @ 4 cfm(2Hp Twin Cylinder Single/Three Phase) All moving parts, machine frame covered by SS sheet metal of good gauge and finish. Panel box inbuilt carrying timers, Temperature controllers and operating switches.

Weight : 100-1000kg

Voltage : 110V

Condition : New

Automatic Grade : Semi Automatic

Power : 1-3kw

Driven Type : Electric

...moreOpening Hours