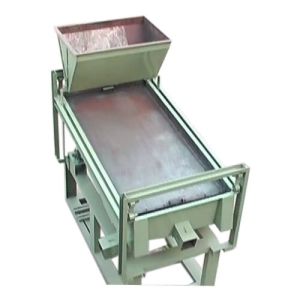

Whole Supari Destoner

The Destoner works as a densimetric separator of the stones from the required product (supari or grains). It separates the different impurities by weight. Its design and working principle allows the separation of stones, glass, peel and iron particles from supari or grains. Destoner for whole supari / grains Application : Wide variety of applications through broad range of products and throughput capacities. • The destoner is described by its wide assortment of conceivable applications: Beside standard applications for wheat, rye, and maize, the machine can likewise be utilized as a part of claim to milling plants for handling oats, buckwheat, grain, spelt, and millet. The destoner is additionally even connected effectively in bottling works, refineries, and ethanol creation plants. Working Principle : Gravity destoner is based on the proportion of different food grain and gravel and suspension speed, the grain size and grain shape approximate grain sand and other debris separated from the machine.

...more

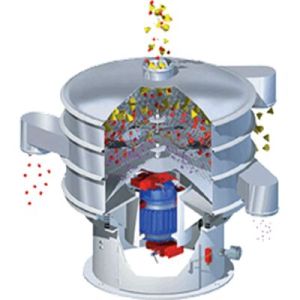

Vibro Sifter

Vibro-sifter is used in the bolting of difficult-to-sift materials such as bran flours and filter flours. Its field of application ranges from wheat, durum wheat, maize and rye milling to specialty milling of oats, buckwheat, barley, spelt and millet. Working Principle : Sieving is a simple technique for separating particles of different sizes. A sieve such as used for sifting flour has very small holes. Coarse particles are separated or broken up by grinding against one-another and screen openings. Depending upon the types of particles to be separated, sieves with different types of holes are used. Sieves are also used to separate stones from sand. Application : Used to separate different types of impurities from the required material based on its size.

...more

Tray Oven

Tray dryer cabinet is a simple large steel or wooden box fitted with internal runners to support the trays of food being processed. The trays are loaded into the chamber, the doors closed and heated air is blown through the stack of trays until the entire product is dry. As the hot air enters below the bottom tray, this tray will dry first. The last tray to dry is the one at the top of the chamber. The advantages and disadvantages of this system are : • Simple, low cost chamber • low labor costs – simply load and then unload • a tendency to over-dry the lower trays • low efficiency, in terms of full consumption, in the later stages of drying when most of the trays are dry. Working Principle : The dryers are made of trays held in a cabinet which is connected to a source of air heated by gas, diesel or bio-mass such as rice husk. The air temperature is usually controlled by a thermostat. The air enters the bottom of the chamber below the trays and then rises, through the trays of food being dried, and exits from an opening in the top of the chamber. In the Practical Action systems the trays are designed to force the air to follow a longer zigzag route which increases the air/food contact time and thus improve its efficiency. This system also reduces back pressure which means that cheaper, smaller fans can be used. Application : It has wide range of applications in food industry, agricultural industry, Pan Masala industry, Pharmaceutical industry and many more industry which require heating of their products.

...more

Tobacco Sieve Shaker

It is used to separate tobacco leaves from impurities like peel, hemp, polythene and many other impurities that comes with tobacco packed in bags. Working Principle : Sieving is a simple technique for separating particles of different sizes. A sieve such as used for sifting flour has very small holes. Coarse particles are separated or broken up by grinding against one-another and screen openings. Depending upon the types of particles to be separated, sieves with different types of holes are used. Sieves are also used to separate stones from sand. Application : Used to separate different types of impurities from the required material based on its size.

...more

supari dryer

It is used to dry and roast supari or grains to remove the moisture and bring it to desired value of moisture content. For customer’s convenience, the dryer comes in different sizes and discharge sides. Our range starts from 10 kg. To 10 Tons per batch. Working Principle : When dryer is switched on, the blower sucks in cold air from the atmosphere and transfers it to the oil fired air heating chamber. The automatic burner operates on reverse flame principle to enable maximum thermal efficiency. The heater is indirectly fired to prevent mixing of flue gases with the hot air. Now this hot air flows in to supari chamber through Multi Fin Point. Hence each grain of supari gets absolutely equal heat. Heat recovery unit installed in it helps to increase the efficiency of the dryer. The indirect oil fired heater has fully automatic self igniting imported burner assembly with horizontal firing, pressure atomizing, forced draft type with direct electric spark ignition. The burner is installed on form side of plant. The burner is imported from F.B.R. Italy with world class spare parts from reputed companies like sequence controller from Landis & Gyr (Germany), transformer from -Cofi / Feeda (Italy), fuel pump form Suntec (France), nozzle from Danfoss (Denmark), motor from Simel / AACO (Italy), photocell from Landis & Gyr (Germany). This ensures trouble free, uninterrupted operation of Dryer. Salient Features More Than 50% saving as compared to electric heater. High Productivity. Low initial Cost. Low running Cost. High quality supari by equal distribution of Hot Air. Space saver & can be easy to be installed at any floor. Application : The dryer manufactured by us has diverse applications : Betel nut (Supari) drying Grains drying Pellets drying The dryer can be used in any drying process where the drying material is in granular form. We also undertake case specific manufacturing of large batch drying processes.

...more

supari cutter

The Supari Cutter is used in the 2nd step of supari treatment. It is used to cut whole supari into desired sizes and shapes. Its wider use is in the automation of Pan Masala manufacturing process. The supari cutter comes with different blades which define the shape and size of the cut supari. Working Principle : Taking into consideration that the betel nut has to be cut into smaller diamond shape pieces and serve the purpose of mass production. The cutting blades are arranged in a particular fashion so that the betel nut or the dry fruits should cut in small pieces suitable for particular use. The force used in cutting of betel nut or dry fruits is shear force. The betel nut or dry fruit is fed into the hopper. From the hopper it enters into the cutting chamber where the betel nut is cut into the small sizes under the action of shearing force between stationary and rotatory blades. The mesh is provided so that after cutting into required size it should pass through it or it will be taken by blades for cutting. Application : Used to cut dry fruits and whole supari. Its high efficiency and ease of use has brought in a great contribution to the food and Pan Masala industry.

...more

silo machine

A silo is a structure for storing bulk materials. Silos are used in agriculture to store grain (see grain elevators) or fermented feed known as silage. Working Principle : The steel structure of the silo provides better strength to the storage tank. These structures are earthquake free. The silo consists of an internal conveyor which prevents material interlocking that hinders flow of the material out of the silo. Application : Silos are more commonly used for bulk storage of grain, coal, ceme

...more

Screw Conveyor

Screw conveyors are one of the most reliable and cost-effective methods for conveying bulk materials. Due to their versatility, screw conveyors can convey a wide variety of bulk materials ranging from dry, free-flowing Portland cement to wet, sluggish dewatered bio solids. Screw conveyors can be designed to operate in almost any position, from horizontal to vertical. Inclined screw conveyors are used to convey and elevate bulk materials from one level to another. Depending upon the bulk material and the objective, proper design and construction of an inclined screw conveyor will provide many years of uninterrupted service and productivity. The purpose of this article is to help the reader understand the basics of inclined screw conveyor design for various applications. Working Principle : A screw conveyor consists essentially of a shaft mounted screw rotating in a trough and a drive unit for running the shaft. The material is moved forward along the axis of the trough by the thrust of screw thread or flight. The trough is usually of the U-shape. A helical blade is attached to a drive shaft which is coupled to a drive unit. The shaft is supported by two end bearings and intermediate bearings. The U-shaped trough has a cover plate with an opening for loading the conveyor. A discharge opening is provided at the bottom of the trough. The loading and discharging points can be located anywhere along the trough. More than one feed hopper and discharge hopper may be fitted according to the necessity. Application : Conveyor systems are commonly used in many industries, including the Pan Masala, automotive, agricultural, computer, electronic, food processing, pharmaceutical, chemical, bottling and canning, print finishing and packaging. Although a wide variety of materials can be conveyed, some of the most common include food items such as beans and nuts, bottles and cans, automotive components, scrap metal, pills and powders, wood and furniture and grain and animal feed. The principle of material movement along the trough is similar to the sliding motion of a nut along a rotating screw when the nut is not allowed to rotate. The weight of the material and the friction of the material against the wall prevent the load from rotating with the screw

...more

Rotary Dryer

It is used to dry the Khaini leaves and remove the undesired moisture from it. For customer’s convenience, Rotary dryer comes in different sizes and is equipped with a dust collector to ensure less wastage. Working Principle : The dryer is made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under gravity. Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls. This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow). The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer. The gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type. Application : Rotary Dryers have many applications but are most commonly seen in the mineral industry for drying sands, limestone, stones and soil, ores, fertilizers, wood chips, coal, iron sulphate, filter cakes, sewage sludge, etc. It is also applied on food industry mainly for liquids as well as for granular material such as food grains, cereals, pulses, coffee beans, fermented tea leaves, etc.

...more

Ribbon Mixer

A ribbon blender consists of a U-shaped horizontal trough containing a double helical ribbon agitator that rotates within. The agitator's shaft is positioned in the centre of the trough and has welded spokes on which the helical ribbons (also known as spirals) are welded. Since the ribbon agitator consists of a set of inner and outer helical ribbons, it is referred to as a “double" helical ribbon agitator. The materials to be blended are loaded into the blender, typically filling it to between 40 and 70 percent of the total volume of the container. This is generally up to the level of the outer ribbon’s tip. Working Principle : During the blending operation, the outer ribbons of the agitator move the material from the ends to the center while the inner ribbons move the material from the center to ends. Radial movement is achieved because of the rotational motion of the ribbons. The difference in the peripheral speeds of the outer and inner ribbons results in axial movement of the material along the horizontal axis of the blender. As a result of the radial and the counter-current axial movement, homogenous blending is achieved in short time. Blending is generally achieved within 15 to 20 minutes of start-up with a 90 to 95 percent or better homogeneity. The particle size and its bulk density have the strongest influence on the mixing efficiency of the ribbon blender. Ingredients with similar particle size and bulk densities tend to mix faster as compared to ingredients with variation in these attributes. ***Product can be customized with a spray system which will ensure uniform mixing of liquid compound to the product. Application : Suitable for material mixing of pharmacy, food, Pan Masala industry, pesticide, chemical industry, plastic, ceramic, paint, putty, mortar and etc.

...more

Pulse Jet Dust Collector

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air cleaners, which use disposable filters to remove dust. Product description : A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air cleaners, which use disposable filters to remove dust. Application : Dust collectors are used in many processes to either recover valuable granular solid or powder from process streams, or to remove granular solid pollutants from exhaust gases prior to venting to the atmosphere. Dust collection is an online process for collecting any process-generated dust from the source point on a continuous basis. Dust collectors may be of single unit construction, or a collection of devices used to separate particulate matter from the process air. They are often used as an air pollution control device to maintain or improve air quality.

...more

Paddle Mixer

Paddle mixers are used to mix or blend a wide range of materials used in different industries including the food, chemical, pharmaceutical, plastic and mineral industries. They are mainly used to mix different materials using different types of blades to make a good quality homogeneous mixture. They can operate at different temperatures and pressures for mixing different solutions and can also have internal or external heating systems added to them. Options also exist where spray nozzles, CIP, PLC and pneumatic or electric systems can be used. Systems can come equipped with hydraulic or electronic soft start mechanisms so that they start and stop smoothly. Working Principle : The rotating paddles divide and blend sequentially the mass of product and generate a quick and intense movement of each particle through the mixing chamber (convection). Due to the defined angle of the paddles, the mixer shows an excellent axial and radial dispersion. Using choppers, additional energy is applied to the product to break up lumps and ensure the dispersion of any agglomerates or liquids. They are also used for granulation processes as well. The mixing time depends on the desired process and the characteristics of products involved. Application : Suitable for material mixing of pharmacy, food, Pan Masala industry, pesticide, chemical industry, plastic, ceramic, paint, putty, mortar and etc. These mixers have ensure hand type mixing and are widely used in applications where gentle mixing is required.

...more

Industrial Agitators

Industrial agitators are machines used in industries that process products in the chemical, food, pharmaceutical and cosmetic industries, in a view of : • mixing liquids together • promote the reactions of chemical substances • keeping homogeneous liquid bulk during storage • increase heat transfer (heating or cooling) They are devices used to stir or mix fluids, liquids specifically. Working Principle : The agitation is achieved by movement of the heterogeneous mass (liquid-solid phase), to the impeller. This is due to mechanical agitators, to the rotation of an impeller. The bulk can be composed of different substances and the aim of the operation is to blend it or to improve the efficiency of a reaction by a better contact between reactive products. Or the bulk is already blended and the aim of agitation is to increase a heat transfer or to maintain particles in suspension to avoid any deposit. Application : It has wide range of applications in food industry, chemical industry, agricultural industry, Pan Masala indust

...more

Hydraulic Press Machine

A hydraulic press is a device (see machine press) using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever, and was also known as a Bramah press. Working Principle : The hydraulic press depends on Pascal's principle: the pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with a modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force. Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder. Application : Hydraulic presses are commonly used for forging, clinching, molding, blanking, punching, deep drawing, and metal forming operations.

...more

Grain Sifter

Separators are used to separate dust and oversized or undersized particles from the required size. Thereby it is useful to grade the material and further make it cleaner. Working Principle : Sieving is a simple technique for separating particles of different sizes. A sieve such as used for sifting flour has very small holes. Coarse particles are separated or broken up by grinding against one-another and screen openings. Depending upon the types of particles to be separated, sieves with different types of holes are used. Sieves are also used to separate stones from sand. Application : It has a wide range of application in food industry as well as Pan Masala industry. (a) It is useful to grade the mat

...more

ffs packing machine

• Auromatic FFS Machine performs integrated operations from measuring, Bag making, Filling & Cutting to Packaging. • Powder Filling Machine equipped with a photocell apparatus for Powder Filling, Powder Packing, Masala Packing, Chips, Granules, Tablets, Pan Masala, Tobacco and its bye products, Candy, Jaljeera Powder, Detergent Powder, Lerron Powder, Fish Powder, Betel Nut, Concentrates, Tea, Coffee, Disposable Syringes, Pharmaceuticals etc. • Equipped with a photocell apparatus suitable to pack General confectionery, Chocolates, Cracker & other rectangular & square shaped solids. • Equipped with a photocell apparatus suitable to pack Liquid, Paste, Jam, Honey Tomato Ketchup, Shampoo, Soya Milk etc. Application : It has wide range of applications in food industry, chemical industry, agricultural industry, Pan Masala industry, Pharmaceutical industry and many more. Product list for its packing includes but are not confined to: • Grains Flour • Spices • Milk Powder • Coffee Powder • Besan • Haldi Powder • Sooji • Sattu • Detergent Powder

...more

Cut Supari destoner

This product also works on the same principle but instead of whole supari, cut supari with stones, glass, metal and other impurities is input. The end product achieved is clean cut supari. Working Principle : Gravity destoner is based on the proportion of different food grain and gravel and suspension speed, the grain size and grain shape approximate grain sand and other debris separated from the machine. Application : Used to separate cut supari from impurities.

...more

Bucket Elevator

A bucket elevator, also known as a grain leg, is a piece of equipment used prominently in the agricultural, road construction, and mining industries to elevate bulk material. Working Principle : A bucket elevator works by connecting many buckets via chains or a conveyor belt around a powered pulley system. The buckets are first filled with bulk material at the bottom of the elevator. Then the buckets ascend the elevator ramp, until they reach the very top where the material is discharged. The buckets are designed to stay upright to prevent spillage. Application : Conveyor systems are commonly used in many industries, including the Pan Masala, automotive, agricultural, computer, electronic, food processing, pharmaceutical, chemical, bottling and canning, print finishing and packaging. Although a wide variety of materials can be conveyed, some of the most common include food items such as beans and nuts, bottles and cans, automotive components, scrap metal, pills and powders, wood and furniture and grain and animal feed.

...more

Belt Conveyor

Conveyors are able to safely transport materials from one level to another, which when done by human labor would be strenuous and expensive. They can be installed almost anywhere, and are much safer than using a forklift or other machine to move materials. They can move loads of all shapes, sizes and weights. Also, many have advanced safety features that help prevent accidents. There are a variety of options available for running conveying systems, including the hydraulic, mechanical and fully automated systems, which are equipped to fit individual needs. A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. Working Principle : One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more. Application : Conveyor systems are commonly used in many industries, including the Pan Masala, automotive, agricultural, computer, electronic, food processing, pharmaceutical, chemical, bottling and canning, print finishing and packaging. Although a wide variety of materials can be conveyed, some of the most common include food items such as beans and nuts, bottles and cans, automotive components, scrap metal, pills and powders, wood and furniture and grain and animal feed.

...more

Agitator

1 Set(s) (MOQ)

We are offering agitator. model no. total capacity (litres) motor rating (hp) ta -10 10 0.25 ta -50 50 0.5 ta -100 100 1 ta -200 200 1 ta -500 500 2

...more

chemical equipment

Food Processing Equipment

Industrial Equipment

Pharmaceutical Machinery

Be first to Rate

Rate ThisOpening Hours